Hardware Tool Grinding

- Unit Type

- Robotic Grinding Unit

- Robot Brand

- ABB, KUKA, FANUC, or specify the brand

- Robot Weight

- 10kg-50kg

- Sander Machine

- 2-6 set

- PLC Brand

- Siemens, Schneider, or specify the brand

- Grinding Consumables

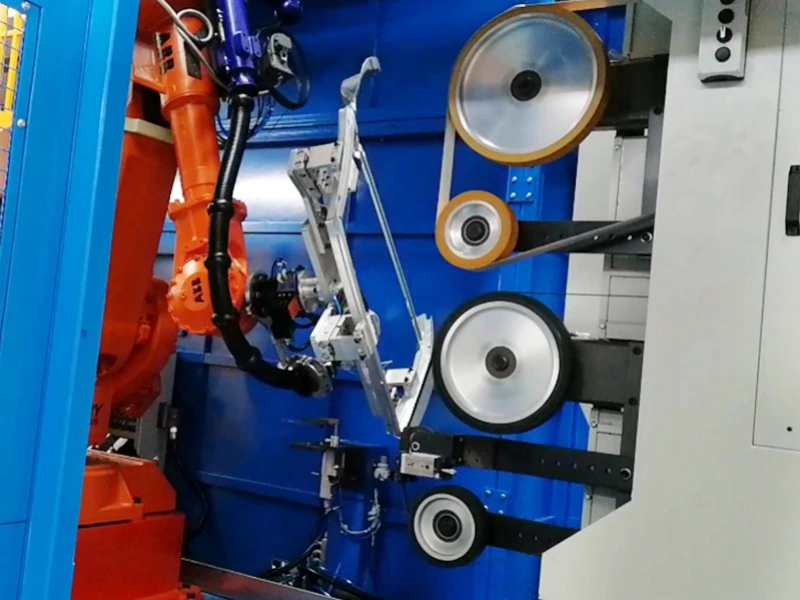

- Sand Belt; foam wheel, sanding wheel, rubber wheel

Hardware Tool Grinding Unit Solutions Introdution

20-60kg Robotic + Singe/double/four work stations sander machine + Dustproof safety room(optional for environmental protection)

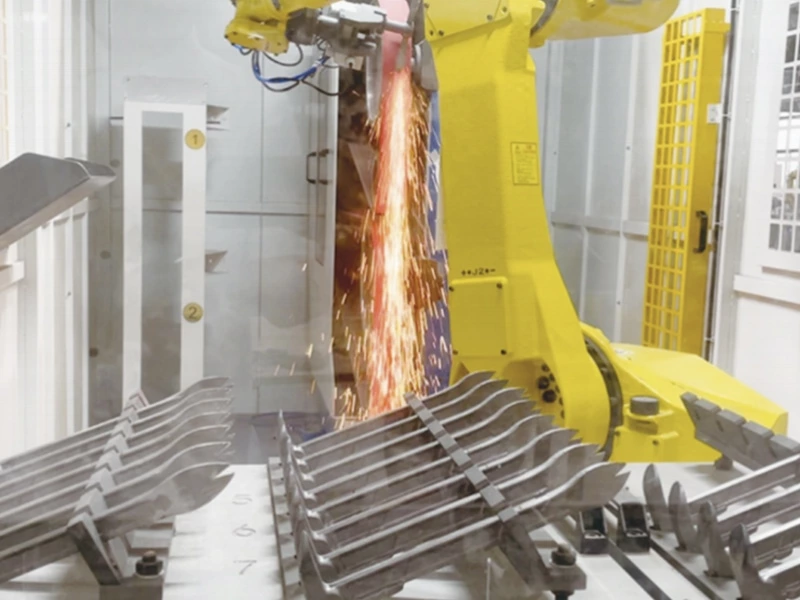

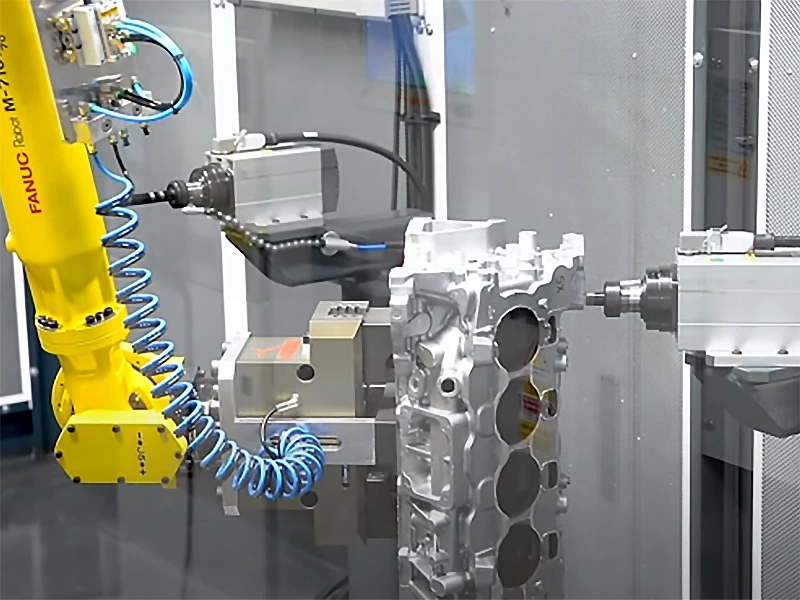

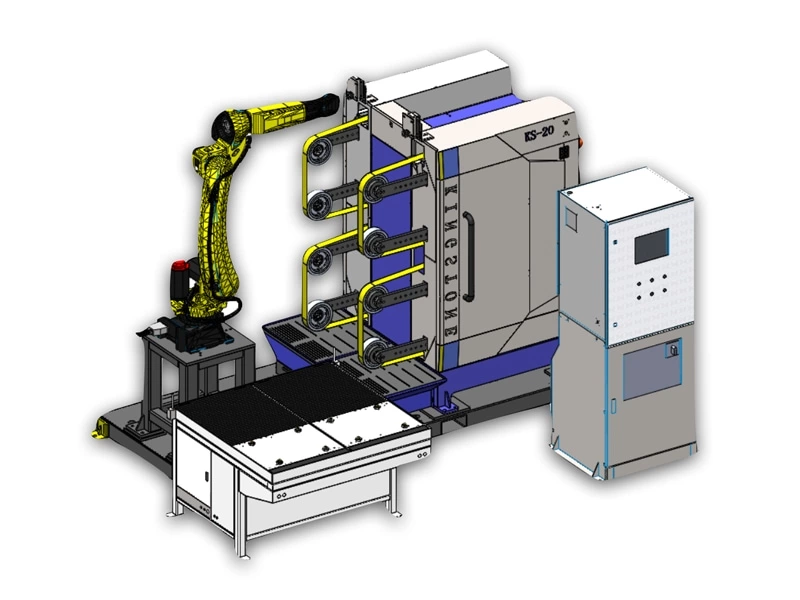

1. Robot grinding unit model

20-60KG Robot arm + Four belt sander machine

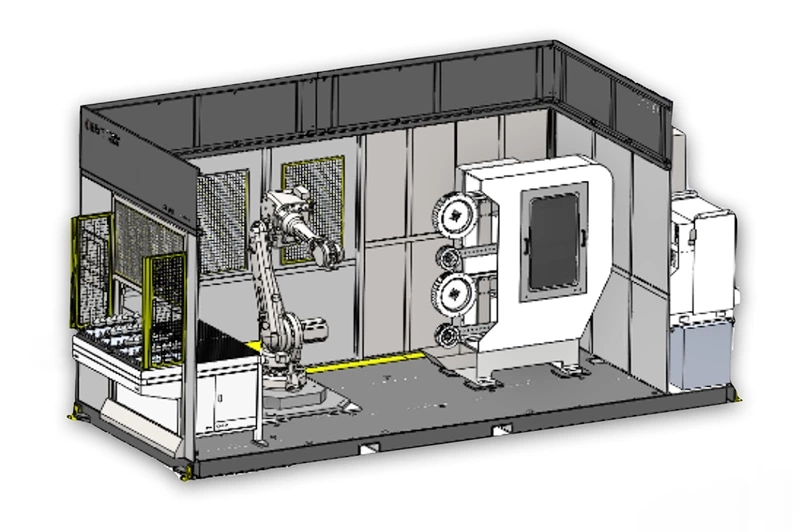

20-60KG Robot + Double belts sander + Dust proof safety room (optional for environmental protection)

2. Six-axis robotic arm

Cooperate with ABB, KUKA and FANUC robots, offline and teaching can be realized simultaneously.

3. Singe/double/four work stations sanding belt machine

4. Electrical control system

PLC, touch screen, control box, electrical control cabinet.

5. System base

The entire system is placed on the base, which is convenient for wiring, debugging, dust removal and cleaning.

6. Other supporting equipment

Robot fixtures, loading and unloading workbench, assembly line body, closed room. Workpiece positioning and pressing fixtures, etc.

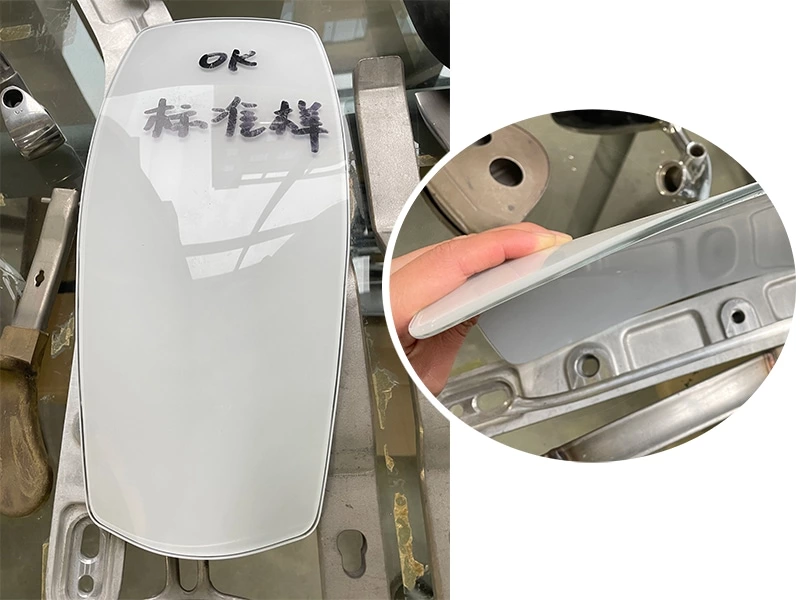

Grinding unit application

Robot grinding are suitable for brass, aluminum, zinc, stainless steel materials, mainly used for grinding in the sanitaryware hardware industry, automotive industry products, clothing hardware accessories grinding, door window industry accessories grinding, bathroom accessories grinding, construction hardware, small household appliances hardware industry, etc. such as hammer body grinding, axe grinding, wrench, shovel polishing, hack saw, chain saw polishing.

Please send your sample pictures to affirm solutions.