Design

Customer requirement (case demo)

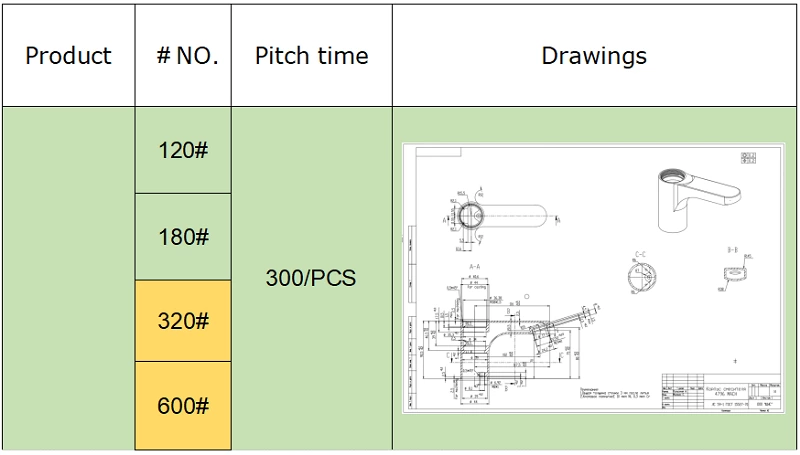

Grinding for products as follows detail:

Product: Faucet & taps

Grinding process: grinding 120#,180#, 320#, 600# after product peeling machine processing (Material: copper alloy)

(If the processing effect of the product peeling machine is too poor, it will increase the grinding time)

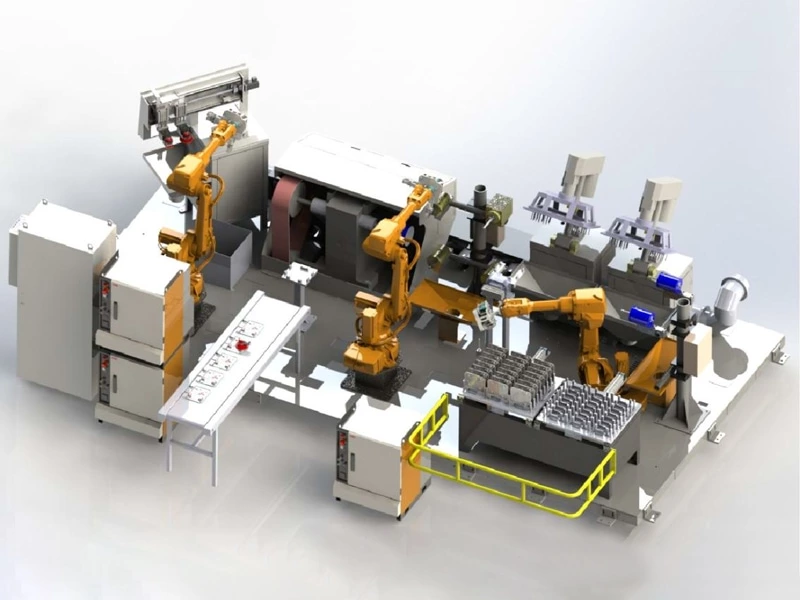

With workshop equipment layout

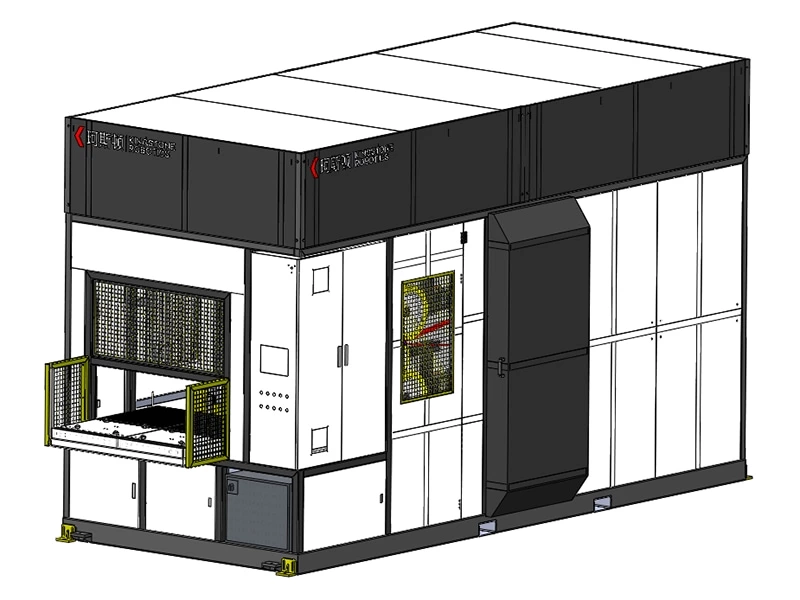

Without workshop equipment layout

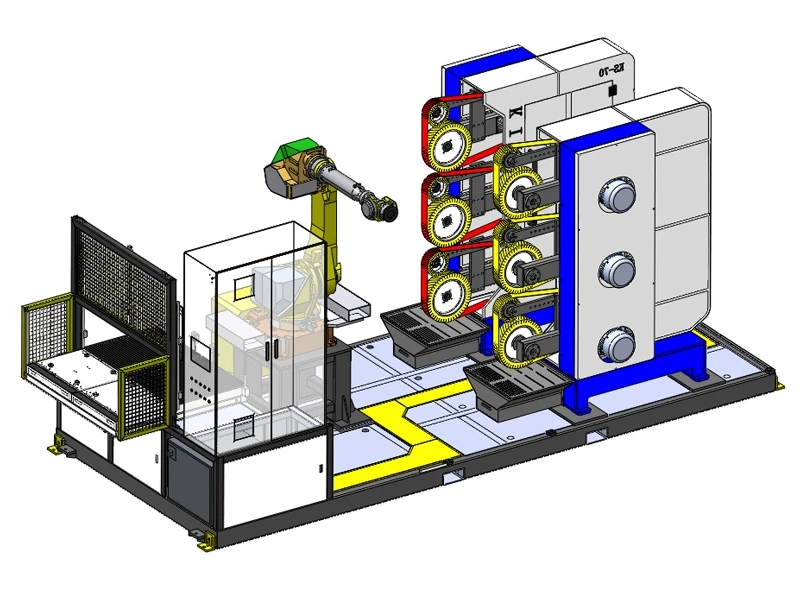

Robot body(FANUC/KUKA/ABB)

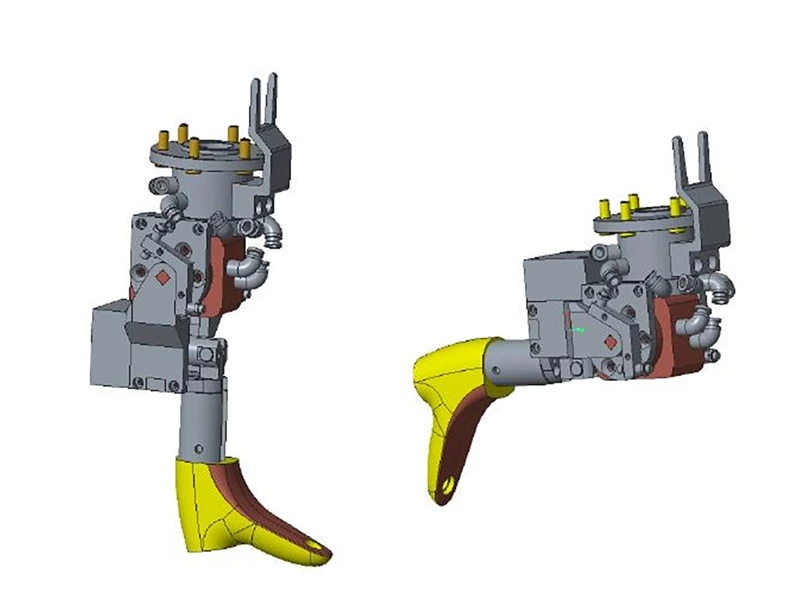

Gripper designed(reference only)

Quotation List

| System | NO. | Items | QTY | Price(USD) |

| Robot Grinding | 1 | FANUC M-710iC/50E(case demo) | 1 | 50000-180000 |

| 2 | Grinding machine (3 belts each) | 2 | ||

| 3 | Robot base | 1 | ||

| 4 | Double position automatic loading table | 1 | ||

| 5 | PLC flexible polishing system | 1 | ||

| 6 | Gripper & trays | 1 | ||

| 7 | Safety room | 1 | ||

| Other | 1 | Programming( KS can provide a set of procedures for direct production) | 1 | |

| 2 | Electrical design fee | 1 | ||

| 3 | Mechanical design fee | 1 | ||

| Package & transport & declaration | 1 | |||

| 4 | After Service(KS provides the robot field operation training in the KS site, and after training can direct operation. | 1 | ||

| Optional Function | 1 | Optional —— Laser detection and correction mechanism | 1 | 20000-40000 |

| 2 | Optional —— Gripper & Tray & Grinding program | 1 | ||

| 3 | Optional —— Cartridge type explosion-proof dust collector | 1 |

Guarantee Period

- Warranty period: one year for mechanical parts and electrical parts, except for human damage.

- The warranty period will take effect after the machine passes the trial.

- The warranty will automatically be voided if any part of the equipment is manipulated or modified by anyone other than KS professional, trained and authorized technicians.

- Any fault or breakdown of the equipment caused by negligence or improper use will be not included in the guarantee.

- Any equipment failure or damage caused by neglect or improper use will not be covered by the warranty.

- KS Technology reserves the right to continue to improve our equipment.

- Robot arm guarantee (take FANUC as an example, the same applies to others): According to the general conditions stipulated by FANUC, the warranty period of the robot arm is 1 year, and any operations related to maintenance or malfunction of the robot are the responsibility of FANUC.

- Overseas installation and maintenance service: Engineer installation and commissioning.