Since 1993

In today’s high-mix, high-variability manufacturing landscape, precision surface finishing is more critical than ever. From automotive and aerospace to medical and consumer goods, every component demands consistent quality and flawless finishing. Yet, traditional manual processes struggle with labor shortages, inefficiencies, and inconsistencies.

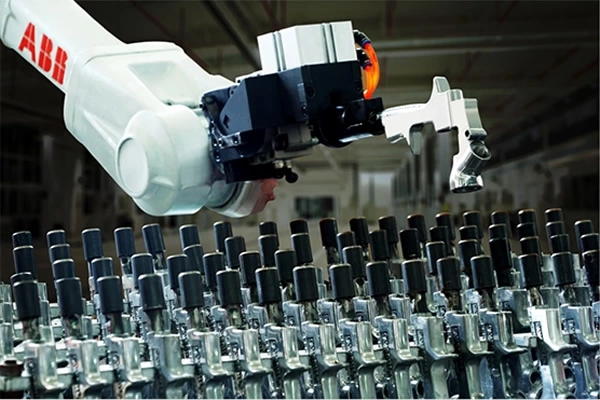

Zhejiang KS Robot & Technology Co., Ltd. is a leading manufacturer of robotic polishing, grinding, and deburring machines, specializing in the development of fully automated surface finishing solutions. At KS Robotics, we deliver robotic automation for grinding, polishing, and deburring, transforming tedious manual work into a seamless, intelligent process. Our advanced systems adapt to material variations, optimize efficiency, and ensure precision at scale, empowering manufacturers to stay ahead in an increasingly competitive market.

What We Do

We develop intelligent robotic solutions for industries requiring high-precision surface finishing, including:

• Bathroom Hardware – Faucets, handles, showerheads

• Automotive – Frames, wheels, engine parts

• Household Goods – Stainless steel cookware, decor

• Medical & Aerospace – Surgical tools, precision components

• 3C Electronics – Metal casings, accessories

Our systems replace manual polishing and grinding with high-speed, adaptive automation, ensuring consistent quality, reduced costs, and higher efficiency.

Technology R&D

KS takes (Sweden) ABB robot company, Germany KUKA company, Japan FANUC company as strategic partners, and establish a cooperation platform integrating industries, schools, and scientific research institutions with the Chinese Academy of Sciences and Harbin Institute of Technology in China, we have developed a series of brand-new product surface polishing and grinding equipment with independent intellectual property rights.

We have central technologies and independent intellectual property rights such as automatic constant pressure system, multi-functional automatic fixture, composite material polishing wheel, and complete software system. The product fills the gap in the "surface polishing" market. Advanced technology enables the robot polishing system to handle workpieces of various complex shapes, and ensures the processing quality of the workpiece and the consistency of the product.

Technical Advantages

At present, large and complex geometric workpieces at home and abroad, such as aviation blades, steam turbine blades, human joints, sanitary ware, hardware tools, etc. Their grinding and polishing surface treatments are all done manually, not only has the disadvantages of low processing efficiency, difficulty in ensuring product consistency, and harsh working environment for production personnel, but also has high management costs.

Full automatic robot flexible processing system grinding and polishing solution, by configuring robot system, grinding and polishing mechanism, interactive grinding and polishing system software, three-dimensional measurement system, etc., realized the automation of complex shape workpiece grinding and polishing, it improves the yield, shortens the surface processing time, and greatly reduces the production and management costs of the enterprise.

What Problems Can Our Equipment Solve For You?

Robot automatic surface polishing unit and automatic control system, can not only polish brass, zinc alloy, aluminum alloy, stainless steel, titanium, and other metal materials, but also can polish non-metallic materials such as plastic and glass.

It is an artificial intelligence operation, automatic control, repeatable programming, mechatronic automatic polishing, and grinding equipment that can complete various operations in three-dimensional space.

This equipment is especially suitable for the flexible production of multiple varieties and large batches in harsh environments. It plays a very important role in stabilizing, improving product quality, improving production efficiency, improving working conditions, and rapid product replacement.