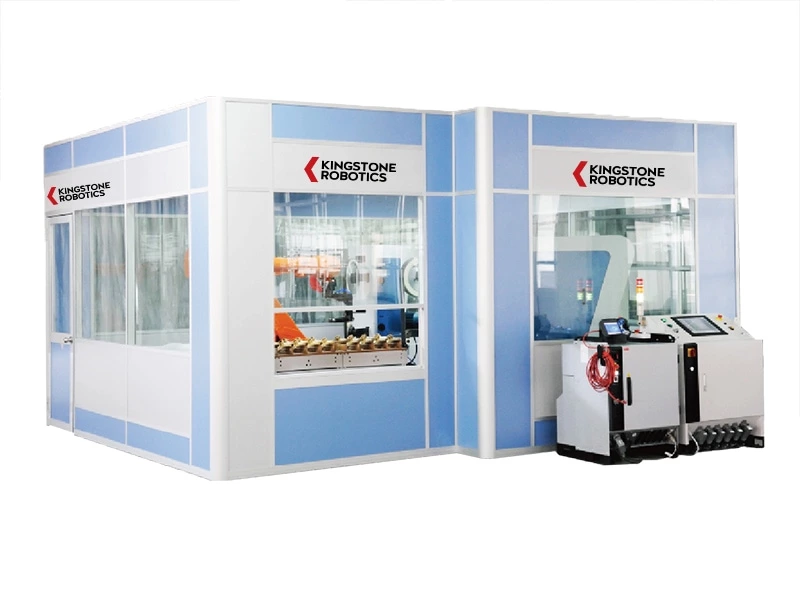

Chair Leg Base Grinding And Polishing

- Unit Type

- Robotic Grinding & Polishing Unit

- Robot Brand

- ABB, KUKA, FANUC, or specify the brand

- Robot Weight

- 20kg-100kg

- Sander Machine

- 2-6 set

- Buffer Machine

- 1-2 set

- PLC Brand

- Siemens, Schneider, or specify the brand

- Polishing Consumables

- cloth wheel, sisal wheel

- Grinding Consumables

- Sand Belt; foam wheel, sanding wheel, rubber wheel

Grinding And Polishing Unit

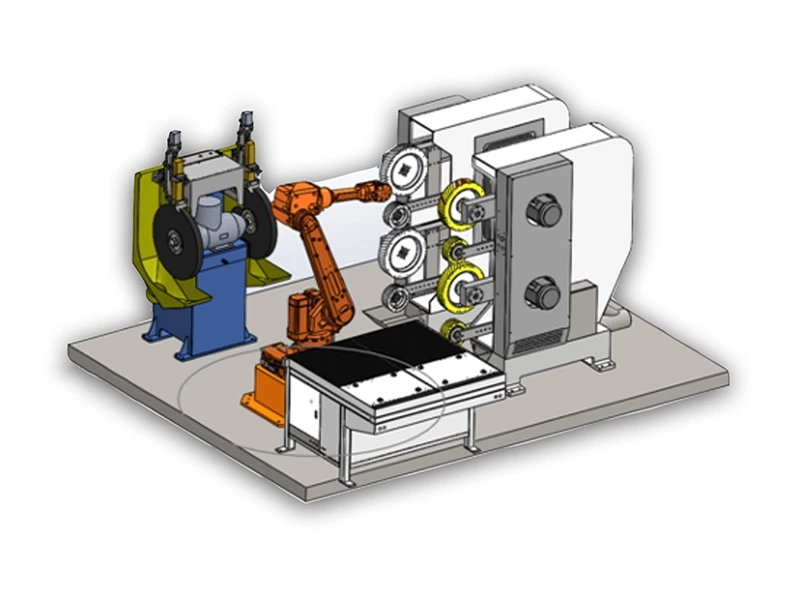

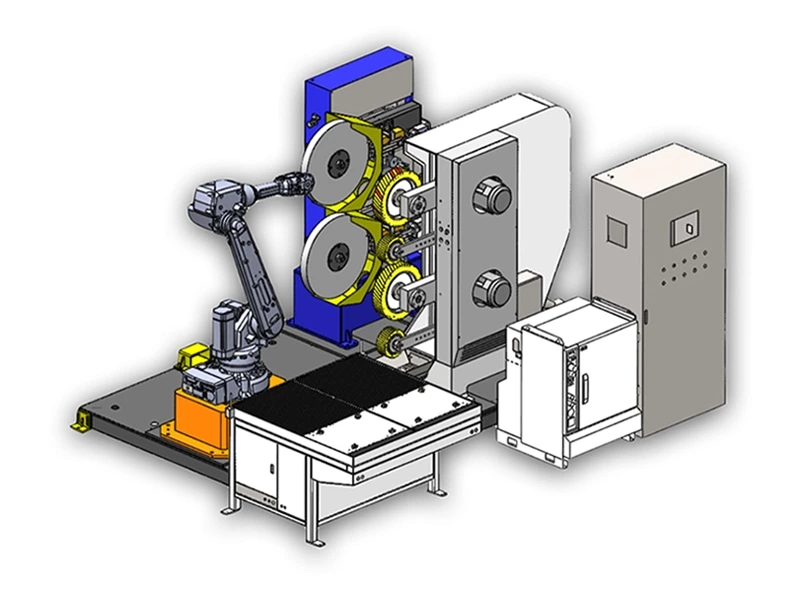

20-60kg Robot + Double/four/six/eight belt sander machine + Cloth wheel/sisal wheel polishing machine+ Dustproof safety room(optional for environmental protection)

KS will design detailed grinding & polishing unit parameters based on the product and the desired grinding and polishing effect. The process of each product is not fixed, we are providing tailor-made automation solutions.

We provide turnkey projects, including fixture design, workpiece 3D drawing generation, equipment layout drawing, floor space 3D drawing and process schematic diagram.

Chair Leg Base Automation Solutions Introdution

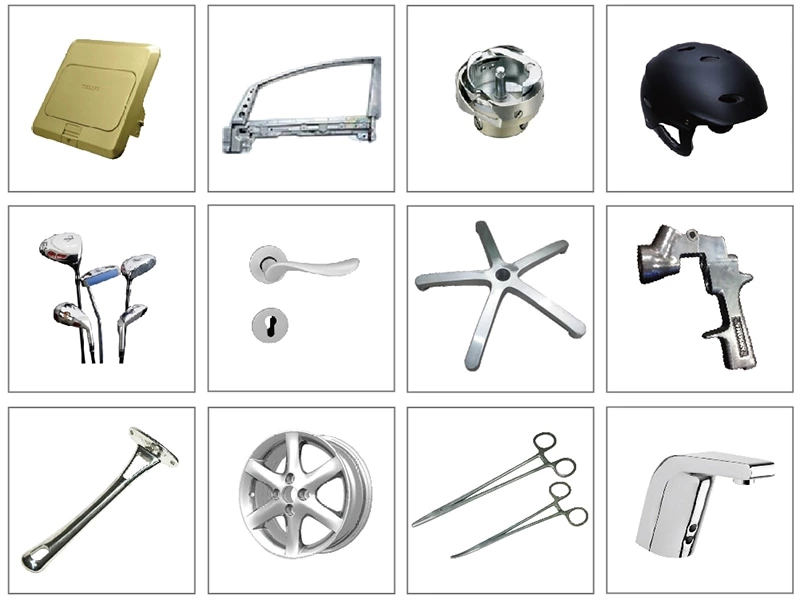

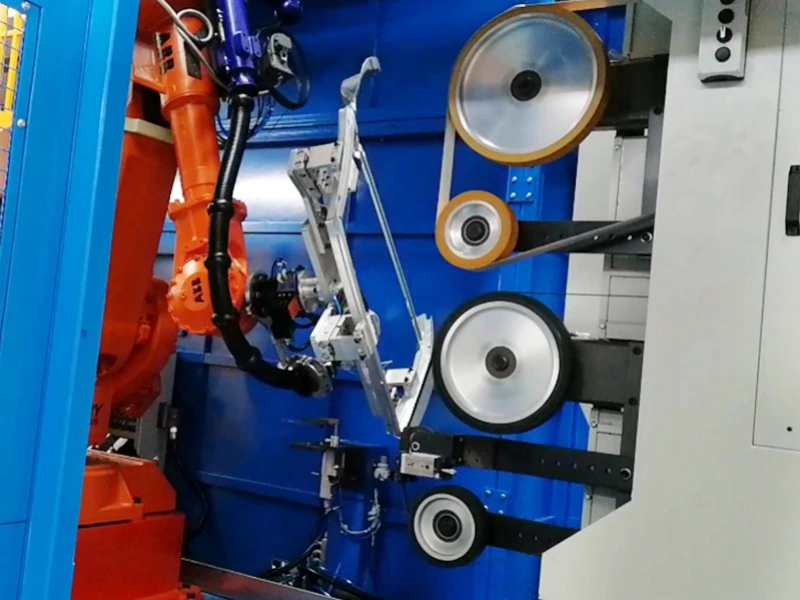

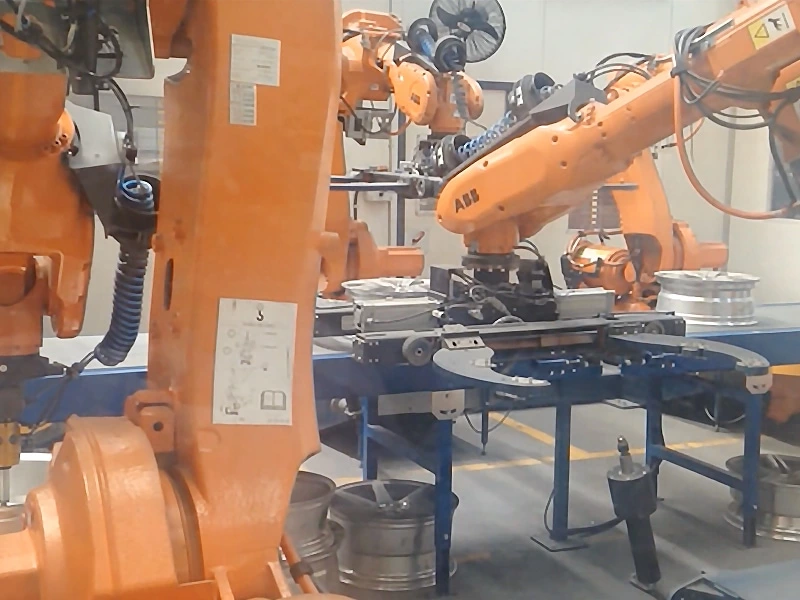

1. Robot grinding & polishing unit demo

20-60kg Robot + Four belt sander + Polishing machine

The number of sander machines and buffer machines (cloth polishing machines) is according to the product quality requirements.

20-60kg Robot + Double belts sander + Two layers polishing machine

2. Singe/double/four work stations sanding belt machine + Polishing machine with cloth wheel / sisal wheel

3. Aluminum chair leg base grinding and polishing completed project case

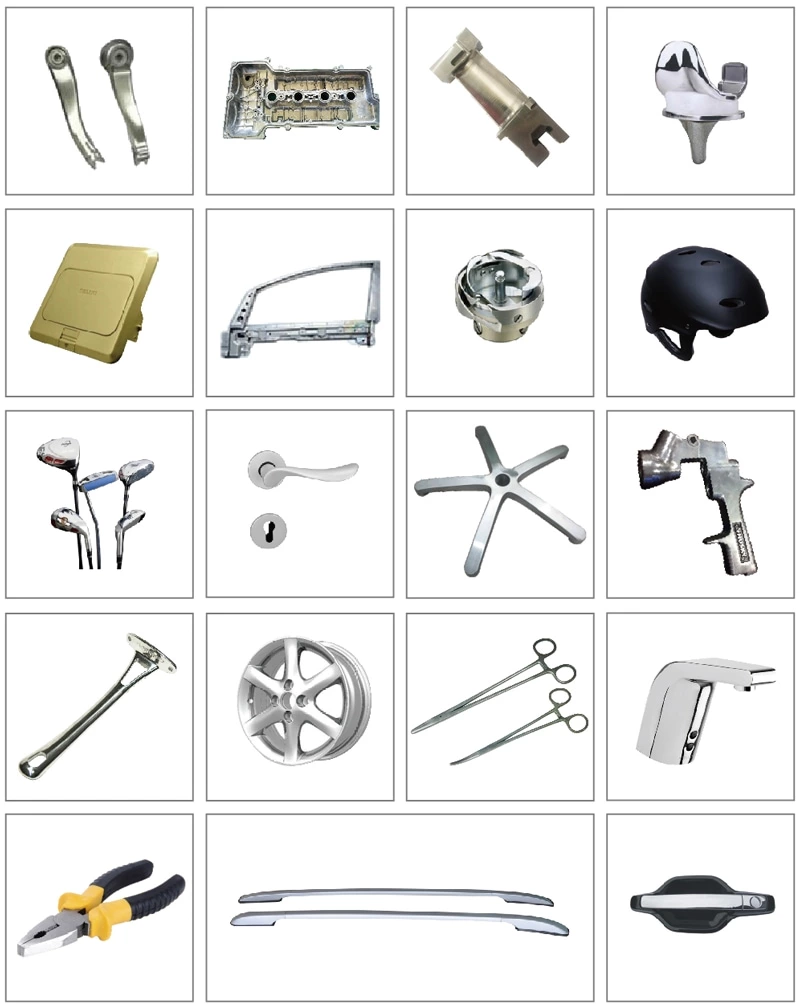

Grinding & polishing unit application

Mainly used for grinding and polishing in the furniture hardware industry, such as furniture legs grinding polishing, solid stainless steel cabinet pull hardware, casterscasters feet and legs, house door buffers, shelf supports, flap hinges, cable outlets, best serve our global customers according to their drawings / samples / specifications.