Drive Axle Grinding And Deburring

- Unit Type

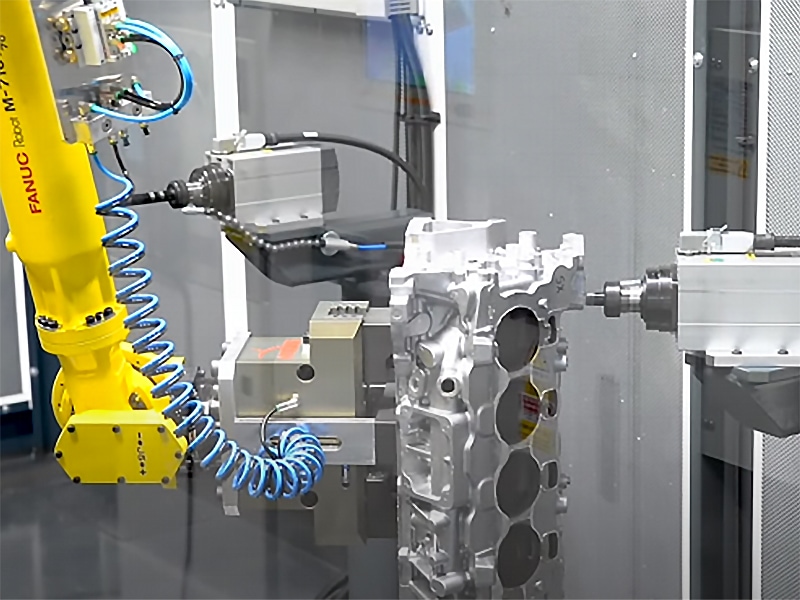

- Robot Grinding and Deburring Unit

- Robot Brand

- FANUC, ABB, KUKA

- Robot Weight

- 60-2300KG

- Sander Machine

- 2-6 set

- PLC Brand

- Siemens, Schneider

- Grinding Consumables

- Sand Belt; foam wheel, sanding wheel, rubber wheel

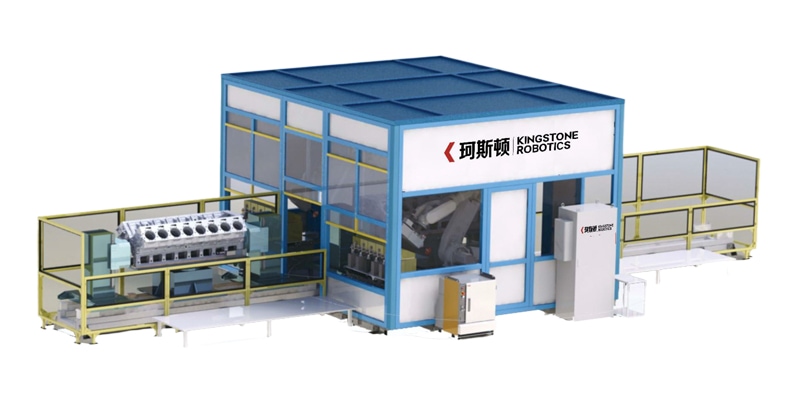

Drive Axle Grinding And Deburring Unit Automation Solutions Introdution

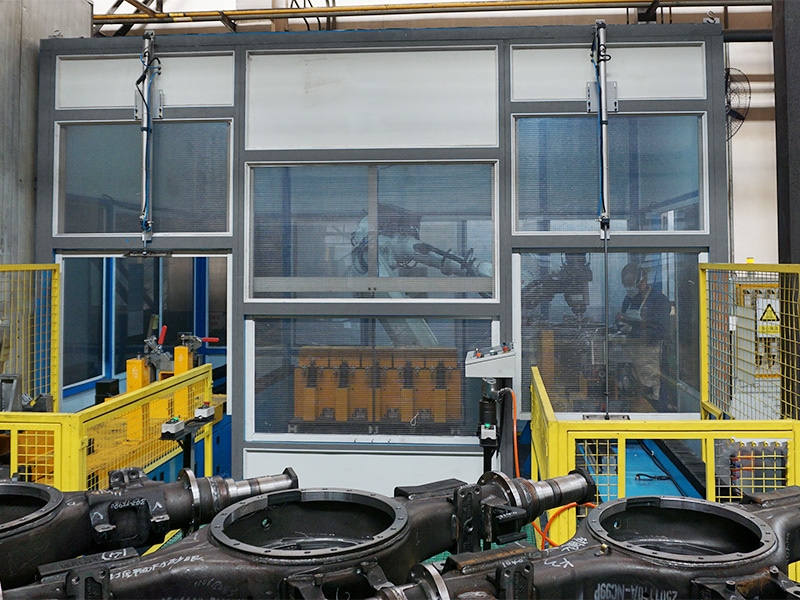

60-2300KG Robot + Deburring tool + Auto delivery table + Dustproof protective house(optional for environmental protection)

The robot grinding & deburring unit workstation is a standard/high-level configuration. The entire deburring process is completed automatically in this workstation at one time.

Since each customer has different quality requirements for large casting drive axle, the processing solutions for same products is not fixed, so we will tailor-made large casting deburring system automation solutions.

We provide turnkey projects, including fixture design, workpiece 3D drawing generation, equipment layout drawing, floor space 3D drawing and process schematic diagram.

Robot deburring unit large casting grinding system

1. Layout can be offline or inline production;

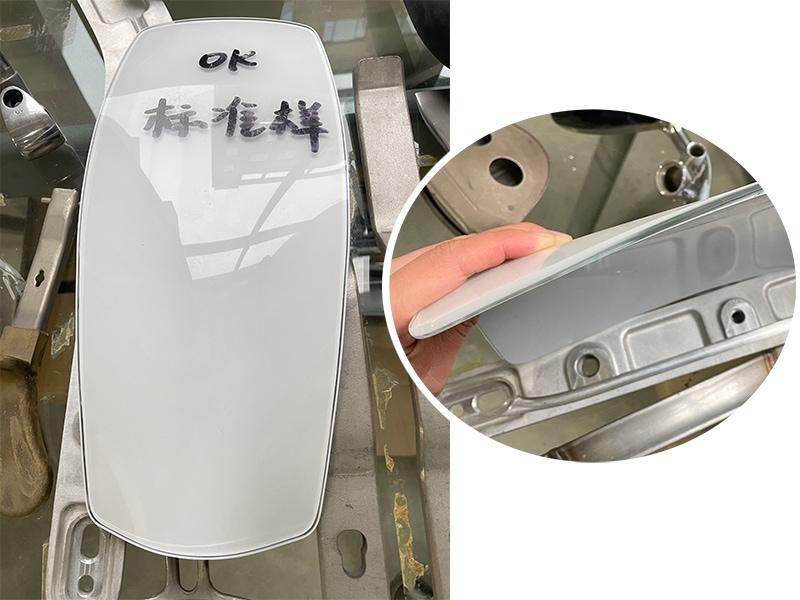

2. Solve the problem of poor consistency of product workpiece characteristics;

3. Economic issues of grinding tools and consumables;

4. Consistency of grinding environment and grinding effect.

Deburring and grinding large castings can be equipped with a dust-proof room, and can be applied to multi-curved surfaces and special-shaped parts of various materials.

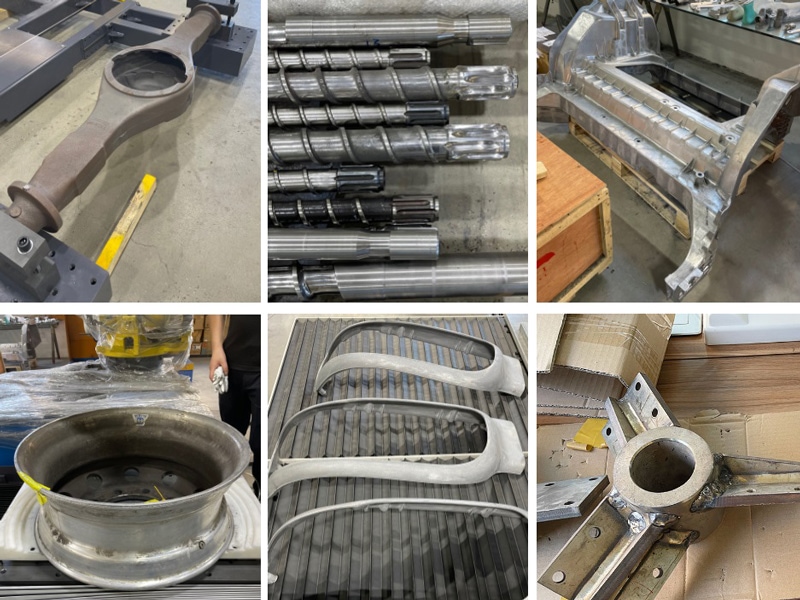

Deburring & grinding unit application

Suitable for lash burr, parting line, burr removal after machining, such as drive axle grinding and deburring, automotive wheel deburring, gearbox grinding and deburring, cast iron casing grinding and deburring, cylinder block, cylinder head, axle housing, reduced shell, etc.

Robot optional ABB-KUKA-FANUC, The robot manipulator can be configured with 60KG to 2300KG. Best serve our global customers according to their drawings / samples / specifications.

KS robot-integrated cells for automatic deburring of large workpieces such as drive axles reduce unit costs and achieve high repeatability in productivity using single or multiple robots.