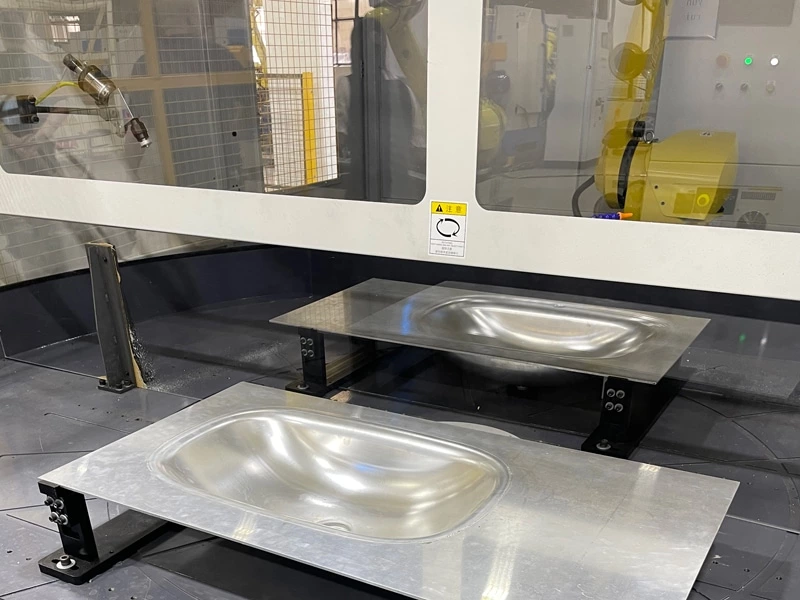

Stainless Steel Wash Basin Grinding And Polishing

- Unit Type

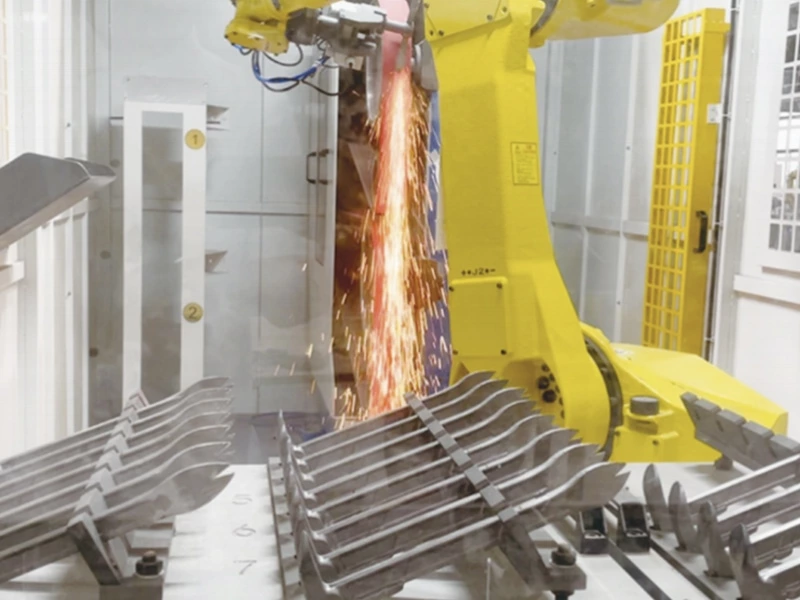

- Grinding And Polishing

- Robot Brand

- FANUC, ABB, KUKA

- Robot Weight

- 60-2300KG

- Sander Machine

- 2-6 set

- Buffer Machine

- 1-2 set

- PLC Brand

- Siemens, Schneider

- Polishing Consumables

- Cloth wheel, sisal wheel, sand flap wheel

- Grinding Consumables

- Sand Belt; foam wheel, sanding wheel, rubber wheel

Automatic Robotic Grinding And Polishing Solutions

1. Customer requirement

Grinding for products as followed detail:

Product: stainless steel wash basin

Grinding process: curved surface grinding+polishing (schematic picture for reference only)

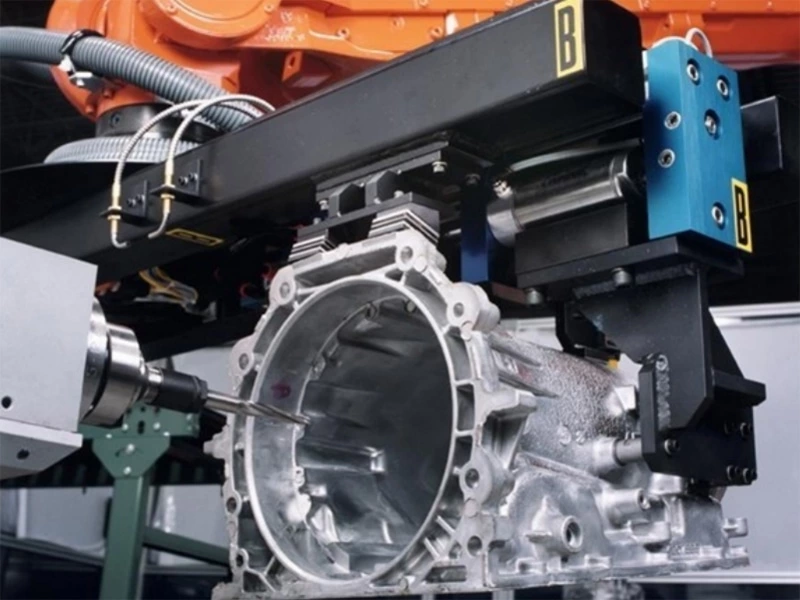

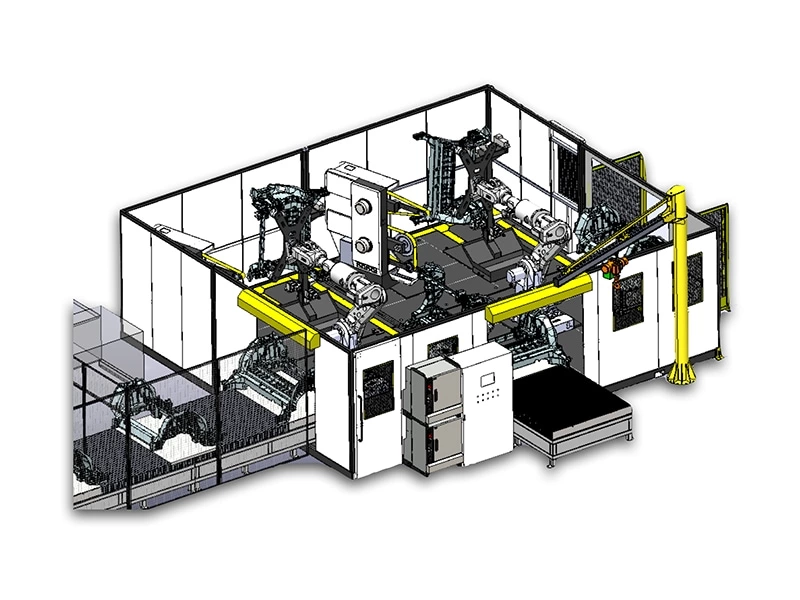

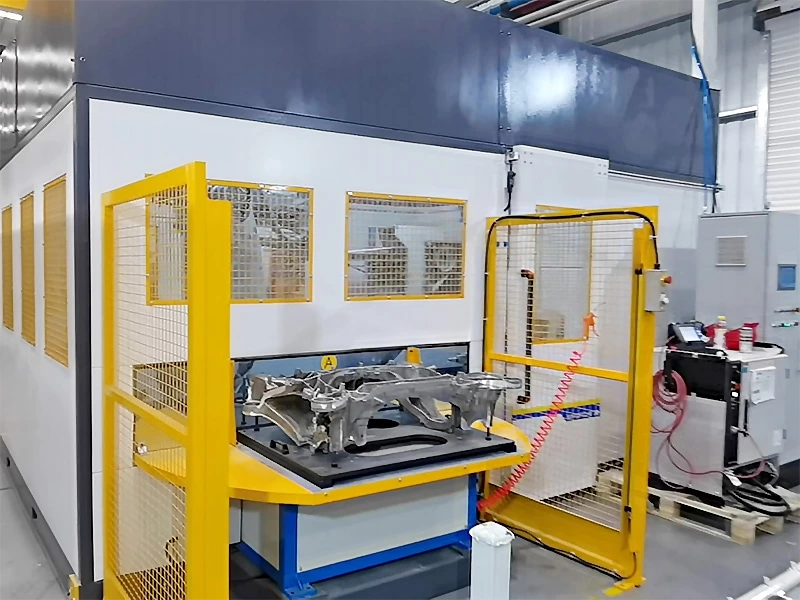

2. Configuration - Robotic grinding cell

- Grinding machine: grinding/sander machine can be hanged with 1-4 abrasives and equipped some special devices to do trimming / rotary / wire brush.

- PLC controller cabinet: The HM interface designed in English and Chinese version(add language as customer require).

- Loading table: with 2 trays automatically in and out. After loading parts on the tray, press the table key, the tray go into the position and send the signal to robot to start polish. After one tray finished,the tray will go out automatically and warn opertator for unloading.

- Applicable Process: Flash burr, parting line, and burr removal after machining.

| Parameter | |

|---|---|

| Dimension | 4400x3400x2900mm |

| Machine Power | 25KW |

| Rated Voltage | 380V |

| Main Axis Motor Power | 4x2.9KW |

| Max.Diameter of Polishing Wheel | 600mm |

| Min.Diameter of Polishing Wheel | 350mm |

| Stoke of X-axis | 1100mm |

| Max.Speed of X-axis | 20m/min |

| Stoke of Y-axis | 900mm |

| Max.Speed of Y-axis | 20m/min |

| Stoke of z-axis | 700mm |

| Max.Speed of Z-axis | 20m/min |

| Stoke of A-axis | +90° |

| Max.Speed of A-axis | 30°/sec |

| Stoke of B-axis | 360° |

| Max.Speed of B-axis | 30°/sec |

| Stoke of C-axis | 360° |

| Max.Speed of C-axis | 30°/sec |

3. Company Introduction

Zhejiang KS Robot & Technology Co., Ltd is expertise in the development and production of high-tech robot grinding/polishing/ deburring system and CNC polishing machine system engineering since 2010.

KS technology can provide 1 set of program to directly product. We provide solutions including design, process, technical documents and drawings, etc.

Customization of the robotic unit with grinding/polishing/deburring, to solve the problem of poor consistency of product workpiece characteristics.