Conveying Pipeline Grinding And Polishing

- Unit Type

- Grinding And Polishing

- Robot Brand

- FANUC, ABB, KUKA

- Robot Weight

- 60-2300KG

- Sander Machine

- 2-6 set

- Buffer Machine

- 1-2 set

- PLC Brand

- Siemens, Schneider

- Polishing Consumables

- Cloth wheel, sisal wheel, sand flap wheel

- Grinding Consumables

- Sand Belt; foam wheel, sanding wheel, rubber wheel

Automatic Robotic Grinding And Polishing Solutions

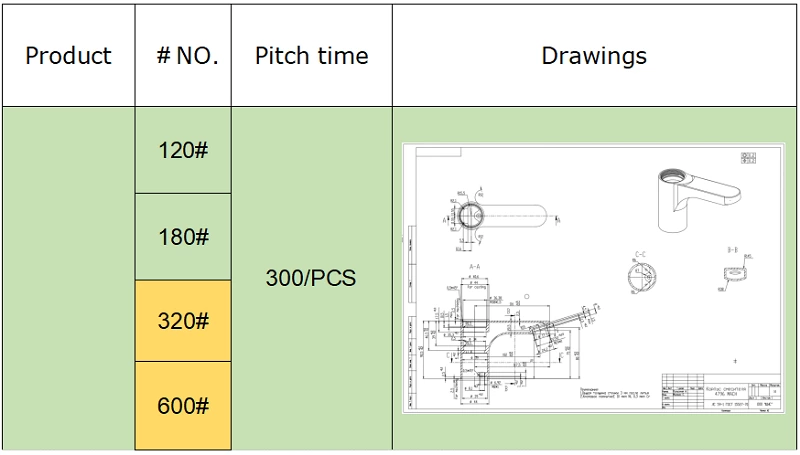

1. Customer requirement

Grinding for products as followed detail:

Product: conveying pipeline

Grinding process: grinding and polishing along the edge of the pipe

(Schematic picture for reference only)

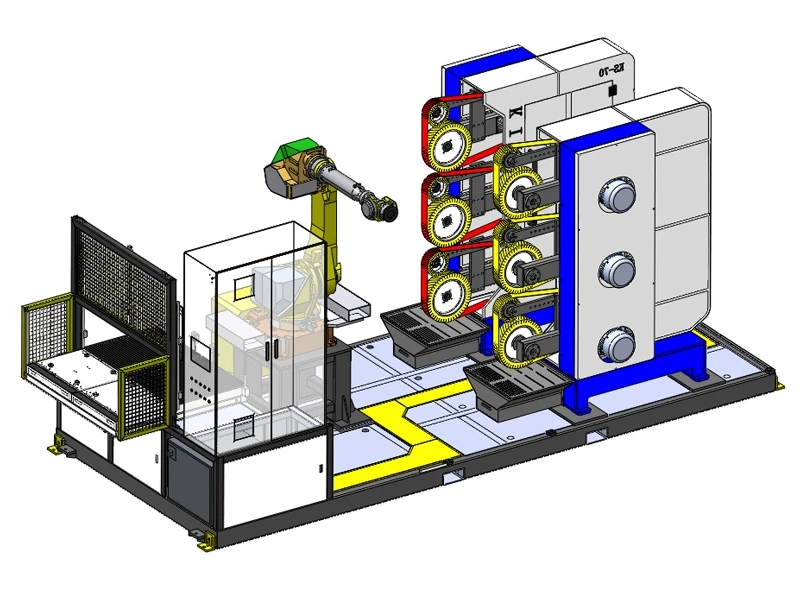

2. Configuration layout - Robotic grinding cell

(Without workshop equipment layout)

(With workshop equipment layout)

- FANUCM-710iC/50E(50KGLoading)

- Flexible force control grinding machine(3 Belts Each)

- Double position automatic loading table

- PLC flexible grinding system

- Safety room

| Technical Parameter | |

|---|---|

| Robotic grinding cell | |

| robot | FANUCM-710iC/50E |

| voltage | 380V (Install transformer if different) |

| Machine Power | 20kw |

| Grinding machine | 2 |

| Sanding belt Qty | 6 |

| Sanding belt length | 4000mm |

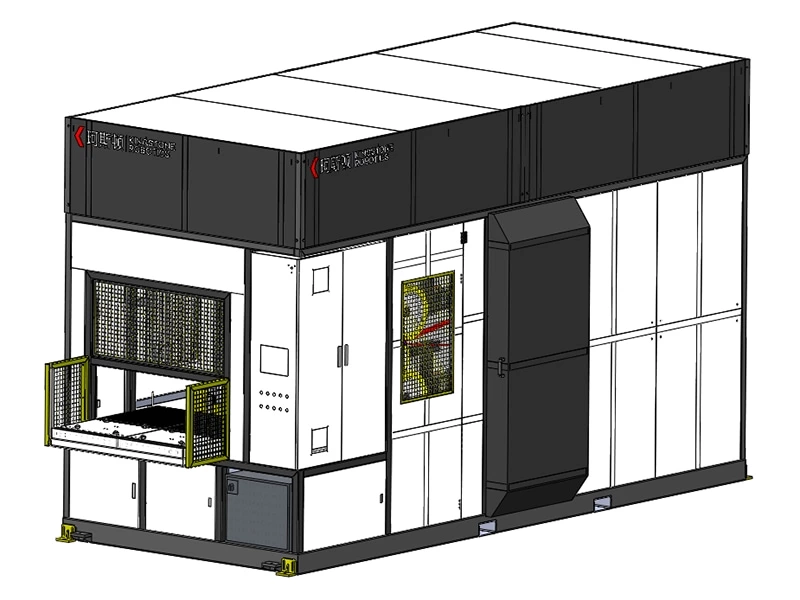

3. KS Introduction

Zhejiang KS Robot & Technology Co., Ltd is expertise in the development and production of high-tech robot grinding/polishing/ deburring system and CNC polishing machine system engineering since 2010. Focusing on robot polishing and polishing more than 10 years.

We provide solutions including design, process, technical documents and drawings, etc. Customization of the robotic unit with grinding/polishing/deburring to solve the problem of poor consistency of product workpiece characteristics.