Car Rear Bilge Grinding

- Unit Type

- Grinding Unit

- Robot Brand

- FANUC, ABB, KUKA

- Robot Weight

- 60-2300KG

- Sander Machine

- 2-6 set

- PLC Brand

- Siemens, Schneider

- Grinding Consumables

- Sand Belt; foam wheel, sanding wheel, rubber wheel

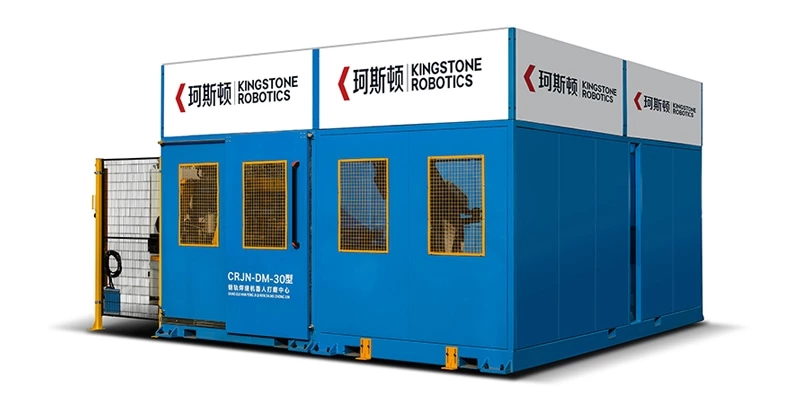

Automatic Robotic Grinding Solutions

KS technology can provide 1 set of program to directly product. We provide solutions including design, process, technical documents and drawings, etc.

1. Company Introduction

Zhejiang KS Robot & Technology Co., Ltd is expertise in the development and production of high-tech robot grinding/polishing/ deburring system and CNC polishing machine system engineering since 2010.

Customization of the robotic unit with grinding/polishing/deburring, solve the problem of poor consistency of product workpiece characteristics.

2. Completed Cases

Customer requirement grinding for products as followed detail:

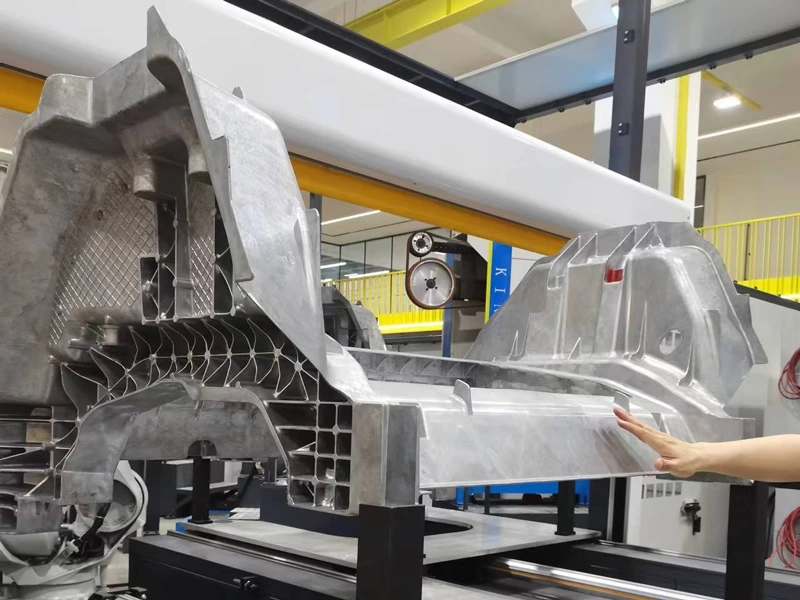

Product: car rear bilge

Grinding process: surface grinding (schematic picture for reference only)

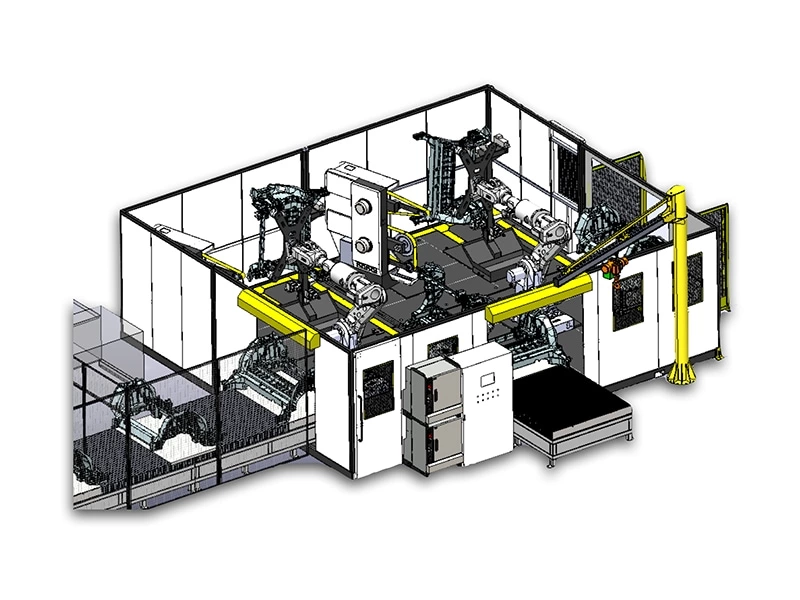

3. Configuration - Robotic grinding cell

- Grinding machine: grinding/sander machine can be hanged with 1-4 abrasives and equipped some special devices to do trimming / rotary / wire brush.

- PLC controller cabinet: The HM interface designed in English and Chinese version(add language as customer require).

- Applicable Process: Flash burr, parting line, and burr removal after machining.

| Technical Parameter | |

|---|---|

| Robotic grinding cell | QTY |

| Robot Base | 1 |

| Grinding machine (3 belt each) | 2 |

| Sanding belt Qty | 6 |

| Sanding belt length | 4000mm |

| PLC flexible polishing system | 1 |

| Safety roon | 1 |