Car Luggage Rack Buffing

- Unit Type

- Robotic Buffing Unit

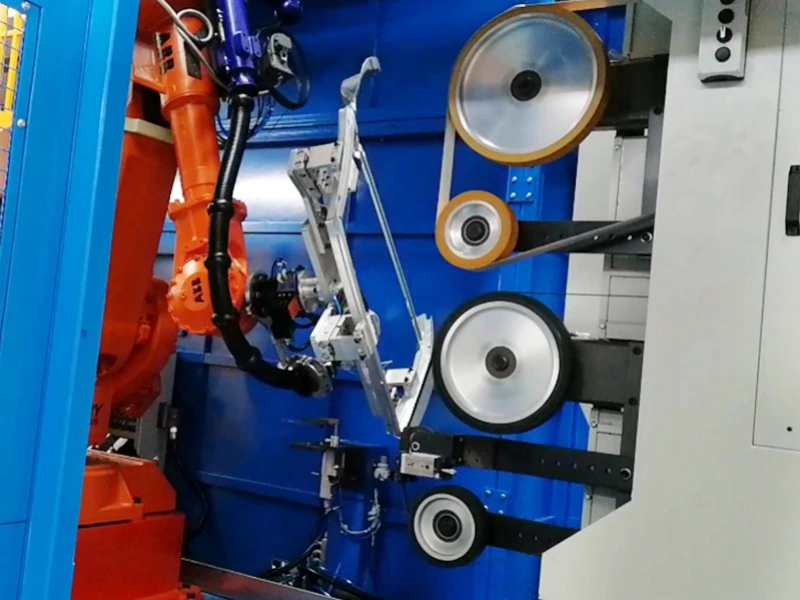

- Robot Brand

- FANUC, ABB, KUKA

- Robot Weight

- 200-2300kg

- Buffer Machine

- 1-6 set

- PLC Brand

- Siemens, Schneider

- Polishing Consumables

- Cloth wheel, sisal wheel, sand flap wheel

Buffing Unit Automation Solutions Introdution

200-2300kg Robotic arm + Cloth wheel/sisal wheel buffing machine+ Dustproof protective house(optional for environmental protection)

KS will design buffing unit workstations based on the product and the customer's desired polishing effect, so even in the same product, the buffing solutions are not fixed.

We provide turnkey projects, including fixture design, workpiece 3D drawing generation, equipment layout drawing, floor space 3D drawing and process schematic diagram.

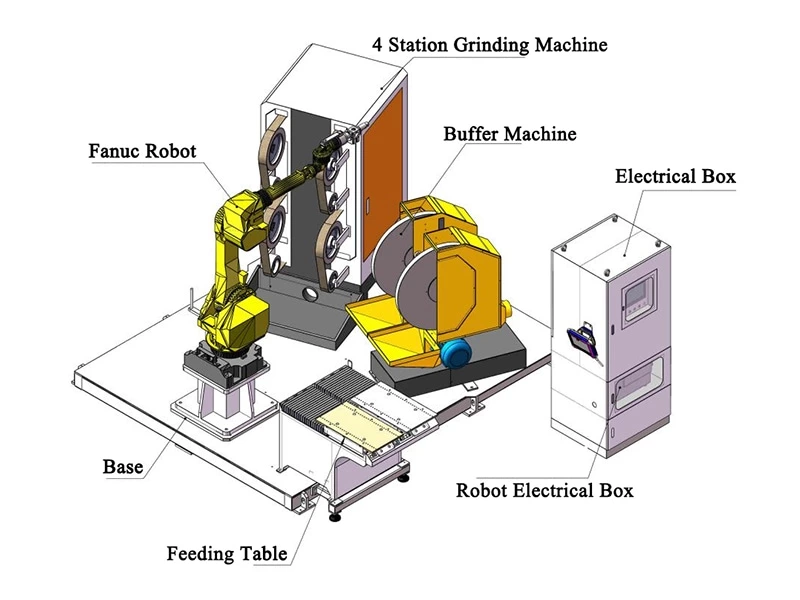

1. Robot buffing unit design drawings

200-2300kg Robot + Four station grinding machine+ buffer machine

The robot buffing unit workstation is a standard/high-level configuration. From product blank to mirror polish, the entire process is completed automatically in this workstation at one time.

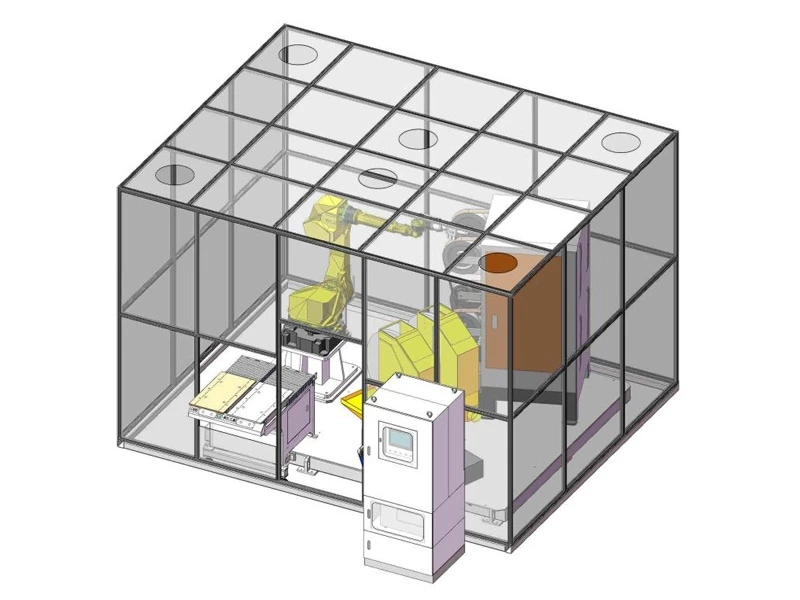

Effect drawing of buffing unit system with aluminum alloy dustproof polishing room (note: aluminum alloy dustproof polishing room is optional)

A dustproof house is an enclosed working cell with soundproofing and fireproofing material, insulating the noise and reducing buffing dust from the inside, keeping the working environment tidy, quiet, and safe.

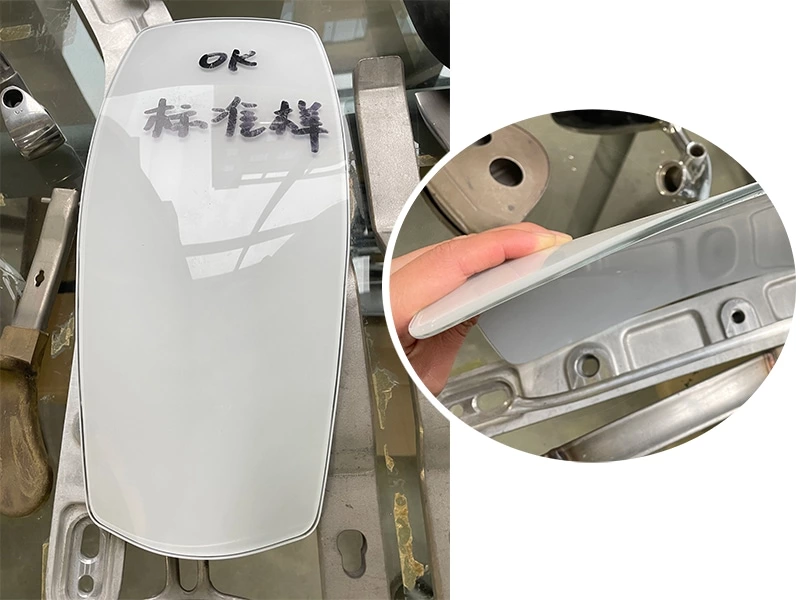

2. Car luggage rack two buffing methods

Buffing one by one

This is buffing brushed directly, and several blanks can be placed at one time

Buffing unit application

Mainly used for large workpiece buffing like cloth wheel buffing, sisal wheel buffing, such as car luggage rack buffing with cloth wheel, car door frame sanding and cloth buffing. Robot buffing unit will also remove things such as stretcher stains, polishing wheel grit lines, light die marks, etc. The robot manipulator can be configured with 200kg-2300kg. Best serve our global customers according to their drawings / samples / specifications.