Brass Water Tap Polishing

- Unit Type

- CNC Polishing

- Polishing Consumables

- Cloth wheel, solid wax

- Control System

- HUST(TAIWAN)

- Servo Drive

- HUST(TAIWAN)

- Switchgear

- Schneider

- Contactor

- SIEMENS AG

Solution Name: Brass Water Tap Six Axis Four Station CNC Polishing Machine

Machine Features

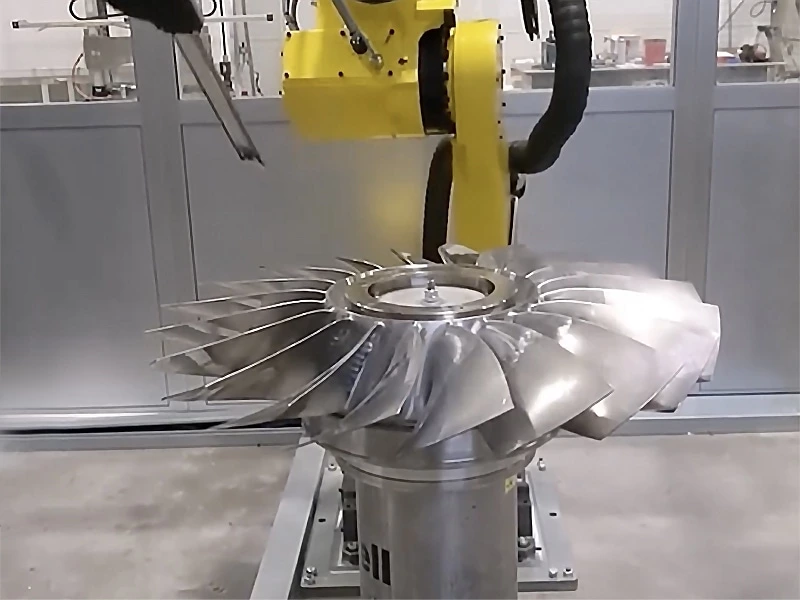

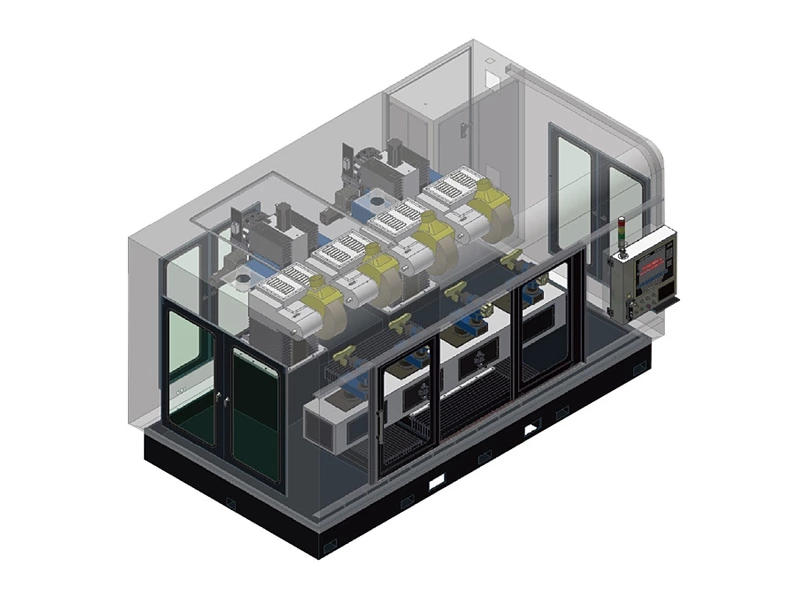

1. This equipment is a special six-axis, four-station intelligent buffing machine with six degrees of freedom, which can synchronously complete the polishing of four workpieces at a time with uniform quality, flexibility and efficiency;

2. The control system adopts HUST(TAIWAN) motion control technology, with stable performance and high control accuracy.

3. Programming method: easy teaching programming, with portable handed device, contains manually mode to simulate the workmanship polishing and record the track.

4. Automatic step-by-step waxing system: the waxing time and frequency can be freely set according to the characteristics of the product, and the automatic compensation of the waxing position can be realized.

5. Full digital control, programs can be saved and recalled at any time.

6. Fast replacement of fixtures and consumables.

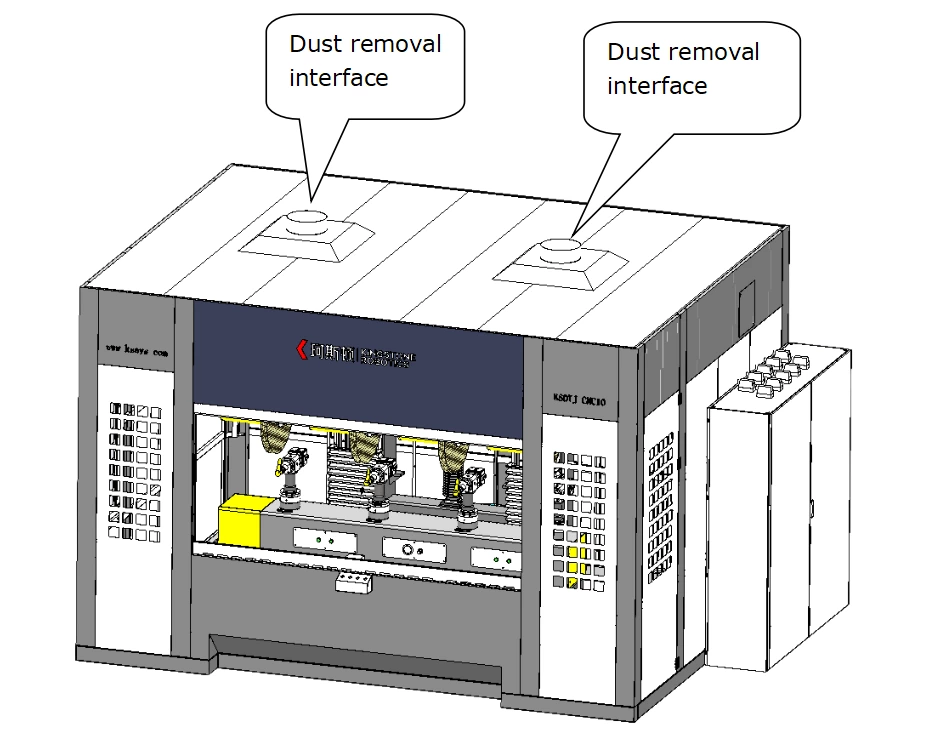

Dust removal interface

KS will reserve 2 dust collecting holes above the workshop (hole diameters according to customer requirements), customers can connect the interface with their own dust control system.

CNC Polishing Machine Safety Working

1. During normal operation of the equipment, the noise value measured outside the protective cover is less than 80 decibels.

2. Emergency stop button, safety check switch: When the safety door or operating window of the device is open, the power system of the device remains completely stopped.

| Description | Unit | Specification |

|---|---|---|

| Table | ||

| Table size (LxW) | mm | 2760*395 |

| Height from ground (without fixture) | mm | 890 |

| Fixture rotating speed | rpm | 20 |

| Number of work stations | 4 | |

| Station size/Working Dia. (max) | mm | 350 |

| Number of Program Stores | set | ≥500 |

| Table Type | Movable - table moving by the screw rod/ball screw. | |

| Driven by servo motor. | ||

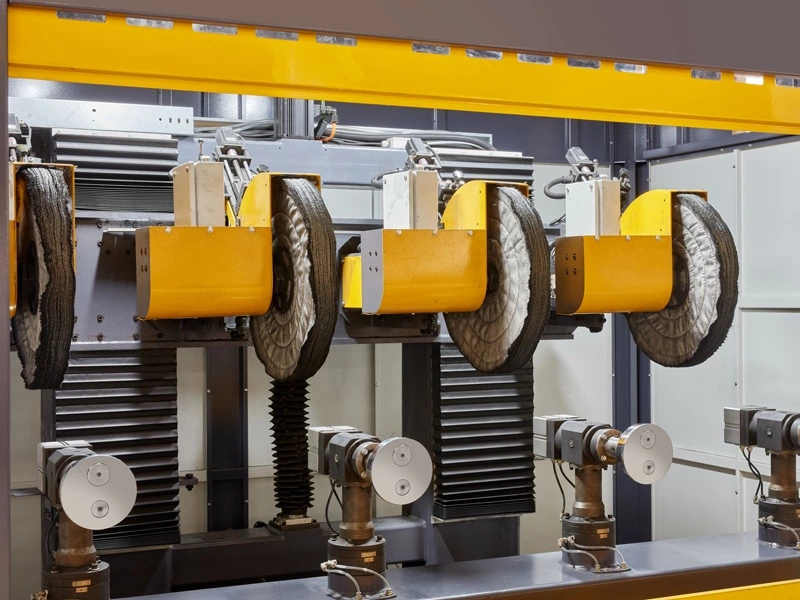

| Buffing/Polishing Heads | ||

| Number of head | 4 | |

| Main Spindle Polishing Motor | KW | 11.6 (4 nos. x 2.9 kw each) |

| Permissible Work Height | mm | 300 |

| Polishing wheel size (consumable) | mm | 600*60*10 mm |

| Polishing compound (consumable) | Type | Solid Wax |

| Polishing compound size (consumable) | mm | 350*60*10 mm |

| Polishing compound application | Automatic device for the solid compound feeding to the polishing wheel on a regular timing basis. | |