Why use robot polishing to polish stainless steel?

Anyone who has learned about the stainless steel polishing and grinding process should know that mechanical polishing of the workpiece surface plays an irreplaceable role in surface treatment processes such as electroplating, painting, and anodizing.

There are still many companies that use manual methods to grinding and polish stainless steel. They use tools to grind and polish the workpiece by hand; or they hold the workpiece by hand and complete the grinding and polishing process on equipment such as grinders.

In fact, deburring by hand or using hand-held pneumatic or electric tools for grinding, grinding, filing, etc. can easily lead to increased product defect rates, low efficiency, and rough and uneven surfaces of processed products. The quality of polishing is judged based on the experience of workers and cannot be guaranteed.

The dust environment at the polishing operation site is extremely harsh. The sparks, dust and noise generated by polishing are very harmful to the physical and mental health of workers. Even if the best vacuum equipment is used, the workshop environment will still affect health.

At the same time, the dust generated during the production process will cause serious pollution to the atmosphere, water sources and other environments.

With the development of the times, the labor force is in short supply, the younger generation is unwilling to enter the industry, wages continue to rise, and production costs are rising. Skilled workers are lacking and work efficiency is low.

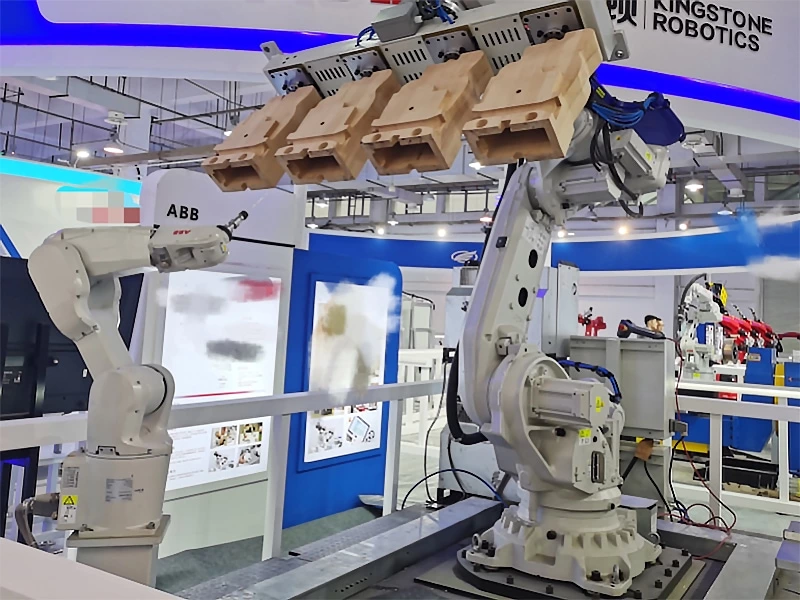

In this context, polishing robots have become more and more popular. Companies are beginning to consider introducing automated systems to replace manual polishing.

Robots are used to replace human hands to handle the tedious stainless steel polishing and grinding processes, effectively improving product quality while saving manpower.

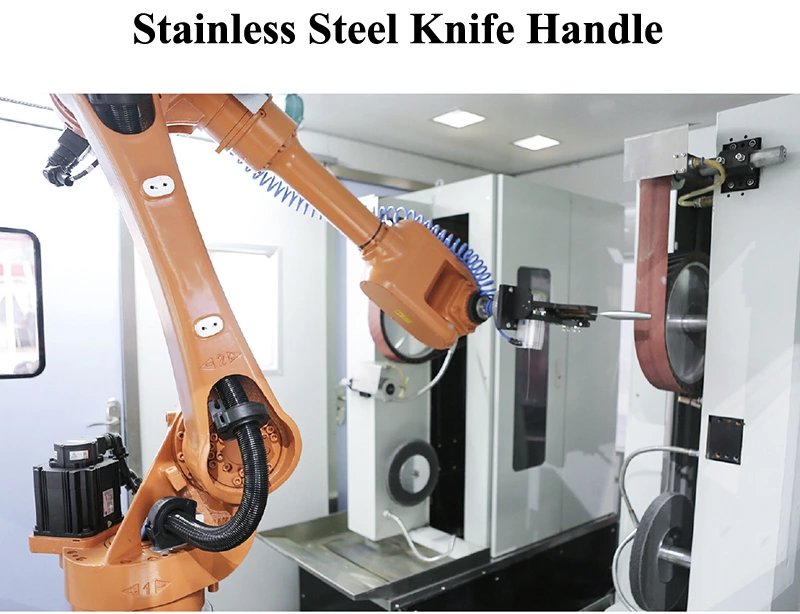

The polishing robot is sealed in the machine room and can work safely in smoke and dust environments. The waste pollution generated during the polishing process can also be effectively cleaned and controlled without polluting the environment or affecting the health of operators.

In addition, the automated robot polishing system can ensure the consistency and accuracy of polished products and avoid product waste caused by inaccurate and uneven manual polishing in traditional processes.

In particular, robot flexible polishing technology has matured and is used in stainless steel polishing, which makes up for the shortcomings of traditional polishing equipment that cannot meet the needs of small batches, complex process requirements, and complex workpiece surfaces.

The robot uses multi-joints of servo motors to imitate the joint movements of human arms to achieve polishing and polishing tasks.

The robot can polish and polish different workpieces, either as a whole or locally.

The entire work process can be completed automatically by the robot, and you only need to press the power button. Currently, robotic polishing plays an important role in the stainless steel industry.

Compared with manual grinding and polishing, robot grinding and polishing workpieces can stabilize product quality, stabilize production, improve product qualification rates, and overcome unstable production quality caused by workers' fatigue or other reasons.

In the polishing process, the precision of the robot cannot be achieved manually, consistent polishing pressure, and consistent polishing curve. Working continuously for a long time shortens the production cycle, improves production efficiency and increases profits.

In this era of super competitiveness, it is a general trend to produce high-demand stainless steel tableware and implement automated polishing processes. If you do not use robots, it will be a matter of time before you fall behind.

The first investment in robotic flexible polishing and grinding equipment is large. If you don’t have your own robot for the time being, you can outsource the business to a trustworthy robot company.

Or as the scale of equipment manufacturing enterprises continues to expand, technical levels continue to improve, and production costs continue to decrease, equipment prices will continue to decline.

The robot polishing system has irreplaceable advantages in the field of finishing workpieces with complex shapes.

It has made important contributions to promoting scientific and technological development and optimizing environmental protection, and its future development is limitless.

It will surely become an indispensable development system in the industrial production stage.