What Is a Robotic Integrator? | Robotic Systems Integration Guide

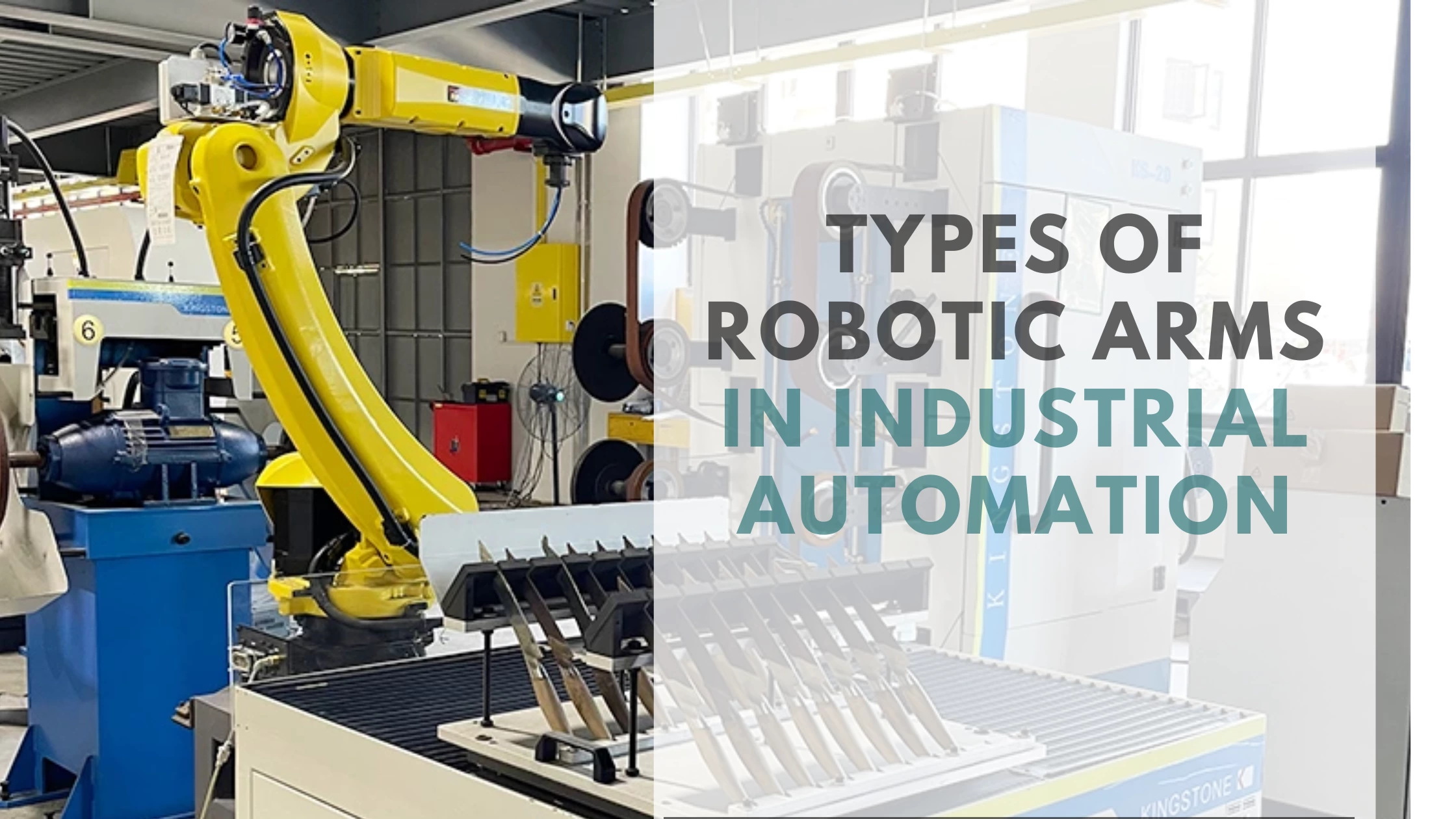

In the age of smart manufacturing, automation isn’t just an option—it’s a strategic advantage. However, deploying industrial robots successfully isn’t as simple as placing an arm on the shop floor. That’s where robotic integrators come in.

You can purchase the best robot on the market, but without thoughtful integration into your unique workflow, it may underperform or even cause production headaches. A robot integrator doesn’t just sell you a machine—they help you build a working solution.This article explores the vital role of robotic integrators in achieving efficient, scalable, and intelligent automation.

What Is a Robotic Integrator?

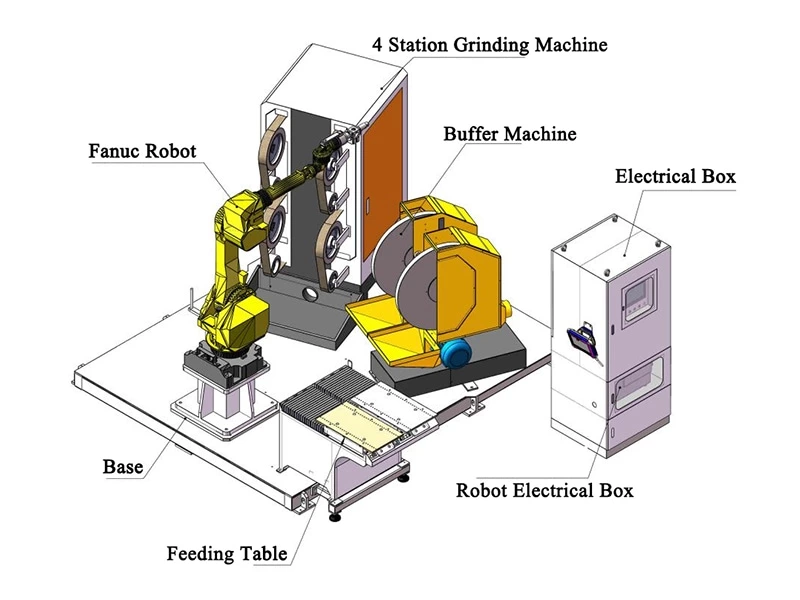

A robotic integrator is a technical partner that specializes in designing, building, and delivering fully integrated robotic systems tailored to a manufacturer’s processes. They combine robots with end-of-arm tooling, sensors, software, safety features, and conveyors—making them work together seamlessly.

While robot manufacturers provide the base hardware, robotic integrators make it usable. Their job is to bridge the gap between standard equipment and specific industrial applications.

More than just installation experts, robotic systems integrators are engineers, project managers, and problem-solvers rolled into one.

And They do not simply sell robots—they deliver complete, operational solutions by integrating robotic hardware with peripheral technologies like:

• End-of-arm tooling (EOAT),

• Safety enclosures,

• Sensors,

• Vision systems,

• Programmable logic controllers (PLCs),

• Human-machine interfaces (HMIs),

• Data connectivity systems.

According to Gomaa (2025), the value of robotic systems in smart manufacturing lies not in individual machines but in how these machines are integrated to interact with the broader ecosystem—including human workers, MES software, and IoT frameworks. Robotic integrators play this orchestration role.

Why Integration Matters: Robots Alone Aren’t Enough

Too often, manufacturers believe that buying a robot is like adding a tool to their workshop. In reality, a robot is more like a blank slate—it needs to be programmed, equipped, and configured to perform any meaningful task.

Consider these challenges:

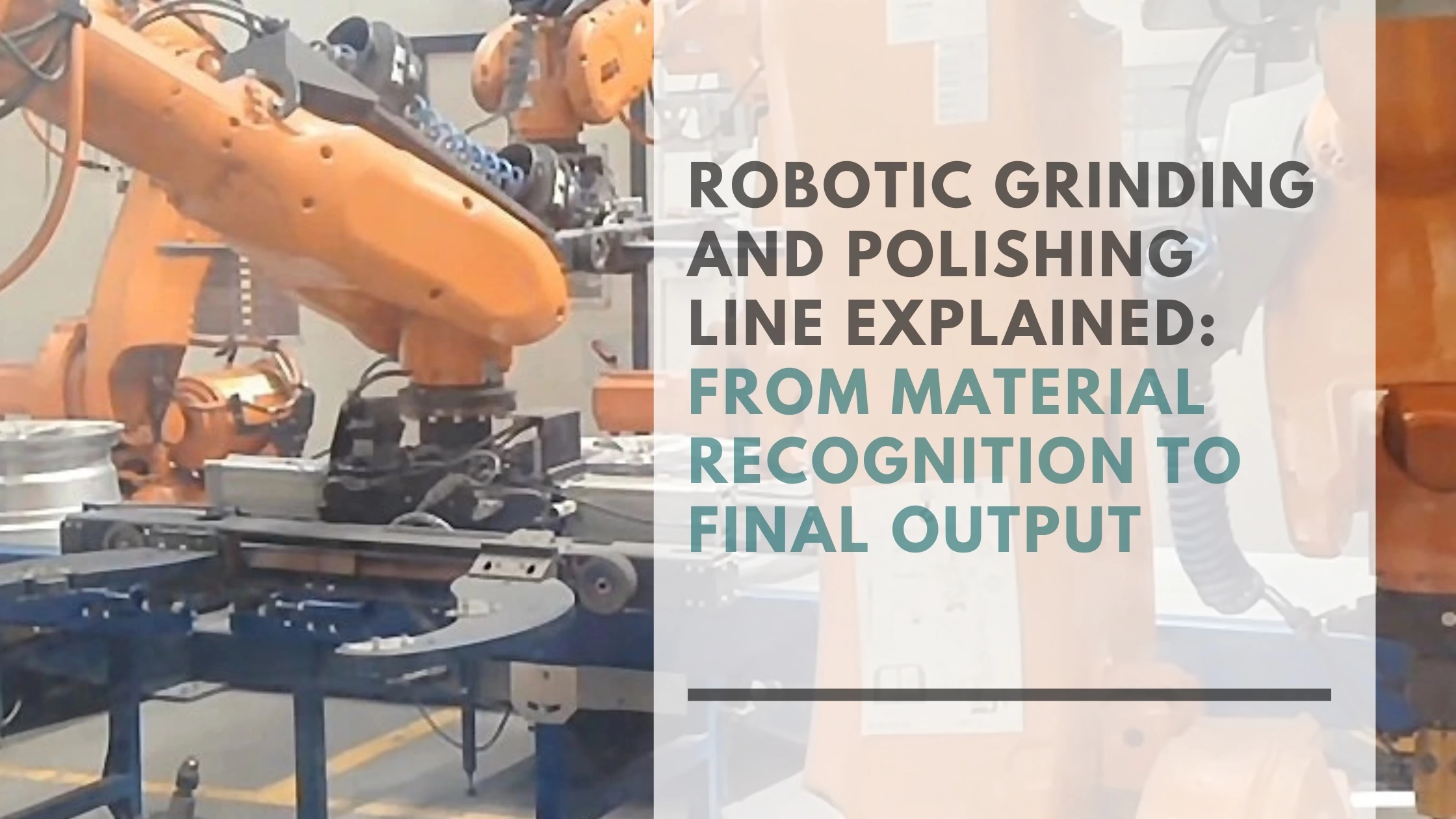

- Application complexity: Grinding, deburring, welding, polishing—each process requires different pressures, angles, motions, and tools.

- Part variability: Robots need vision systems or sensors to handle inconsistencies in incoming parts.

- Safety requirements: Robotics systems must comply with strict standards, especially in human-robot collaborative spaces.

- System coordination: Robots rarely work alone. They must communicate with other machines, control systems, and sometimes enterprise-level software.

A good robot integration strategy makes sure all of these variables are addressed before the first part hits the line. As Azad et al. (2025) point out, system-wide integration is what transforms isolated automation into lean, synchronized production cells, enabling both high throughput and flexibility.

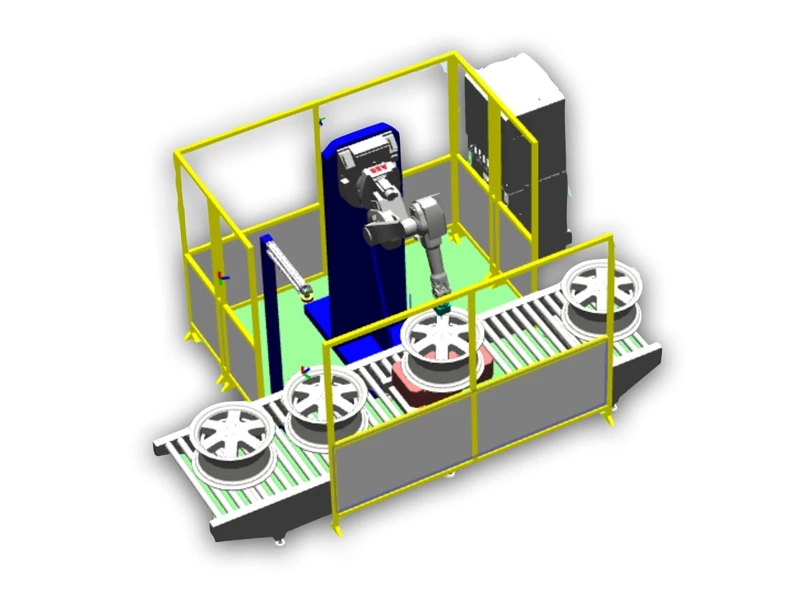

Kingstone Robotics - Automotive Wheel Grinding And Deburring

What Does a Robotic Integrator Do?

From feasibility study to full-scale deployment, robot integrators guide manufacturers through the complete automation journey. Their role typically includes:

- Needs Assessment

They begin by understanding your existing processes, identifying pain points, and determining if robotics will truly add value.

- System Design

Based on your goals, they create a full system layout—specifying robot models, grippers, sensors, control panels, and safety systems. Each design is tailored to the product’s geometry, material, and handling requirements.

- Simulation & Proof of Concept

Many integrators use software simulations and digital twins to test concepts, verify timing, and evaluate collision risks before physical implementation.

- Full Robot Integration

This includes mechanical and electrical installation, PLC or PC programming, user interface development, and integration with existing systems.

- Testing & Commissioning

After setup, the system undergoes Site Acceptance Testing (SAT). This includes: Debugging workflows,Validating safety protocols,Fine-tuning cycle times,Troubleshooting hardware/software mismatches and Training & Lifecycle Support.

They train your operators and maintenance team. A strong integrator also offers long-term support—system upgrades, remote diagnostics, reprogramming for new products, and preventive maintenance—to ensure your robotic system continues to deliver value as your needs evolve.

Who Needs a Robot Integrator?

The simple answer? Any manufacturer looking to automate a complex or high-precision process. But robotic integrators are especially vital for:

- Manufacturers with no in-house automation team

- Custom or variable production environments

- Industries with high safety risks

- High-volume production lines

- Factories under pressure to scale

Integrators ensure the technology fits your actual workflow—not the other way around.

Choosing the Right Robotic Integrator

As with any long-term partnership, choosing the right robot integration company can make or break the success of your project. Here’s what to look for:

- Cross-industry experience

- Technical depth (vision, force control, data integration)

- Turnkey delivery from design to deployment

- Aftermarket support and training

- Strong relationships with robot OEMs

- Scalability and long-term flexibility

Also, trust your gut—do they understand your goals and offer realistic expectations? Great robotic integrators manage complexity while keeping you informed and confident.

Common Missteps Without Integration Support

It’s tempting to cut costs by sourcing components separately or trying to piece things together internally. But that approach often leads to:

- Delays due to mismatched hardware or software

- Inefficiencies from poorly designed toolpaths or slow cycle times

- Operator confusion due to lack of intuitive HMI or training

- Downtime from frequent errors or maintenance issues

- Underutilized robots that don’t reach their full potential

A rogotic integrator—even if you typed it wrong in a search—might just be the partner you’re looking for to solve these issues. (Yes, we’ve seen it misspelled too!). According to Rahmati (2025), intelligent robotic systems fail more often from poor system design than from mechanical limitations. Integration mitigates these risks.

Click To Know More About Kingstone Robotics Service info.

The Strategic Value of Robotic Systems Integration

Let’s be clear: the true value of automation isn’t in owning a robot. It’s in consistently producing better products, faster and safer, with fewer errors and lower long-term cost.

Robotic systems integration makes this possible by delivering:

- Reduced cycle times and labor costs

- Improved repeatability and product uniformity

- Safer working conditions and regulatory compliance

- Adaptability to new product lines or volumes

- Real-time performance monitoring and data tracking

Automation isn't just about speed—it's about control. Integration is what gives robots their intelligence and purpose within your operations.

Final Thoughts: Robots Are Powerful—But Systems Win

A robot arm is impressive. But it won’t replace workers, improve quality, or boost efficiency without a well-planned system around it. That’s why robotic integrators aren’t just vendors—they’re strategic enablers of smart manufacturing.

Whether you're automating a grinding station, polishing complex contours, or assembling small components, robot integration done right will yield long-term advantages.

So the next time you think automation, think beyond the robot itself. Think integration.

Partner with Kingstone Robotics-Experienced Robotic Integrator Since 1993.

At Kingstone Robotics, we help manufacturers across industries take the next step in automation. As a professional robotic integrator, we specialize in grinding, polishing, deburring, and custom robotic systems that work in the real world.

We don’t just deliver robots—we deliver complete, optimized, and scalable solutions that transform your production line.