Robot Faucet Polishing And Grinding Intelligent System

The grinding and polishing workstation will solve the pain points of the plumbing and bathroom industry

Polishing and grinding is the most common basic production process in the manufacturing industry. Depending on the processing accuracy requirements, it can be complex or simple. It is indispensable for heavy machinery, as small as mobile phones, home appliances and even faucets.

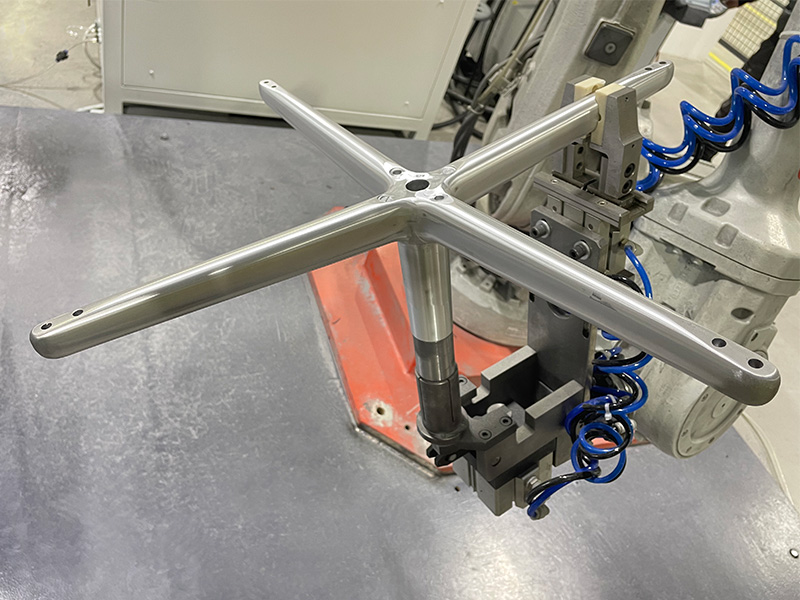

The core of the polishing and grinding workstation is the combination of process requirements and the robot system. The workpiece surface is polished, the edges and corners are deburred, the welds are polished, the inner cavity and the inner hole are deburred, and the orifice and thread mouth processing...each step is interlocking.

Take grinding and polishing faucets as an example

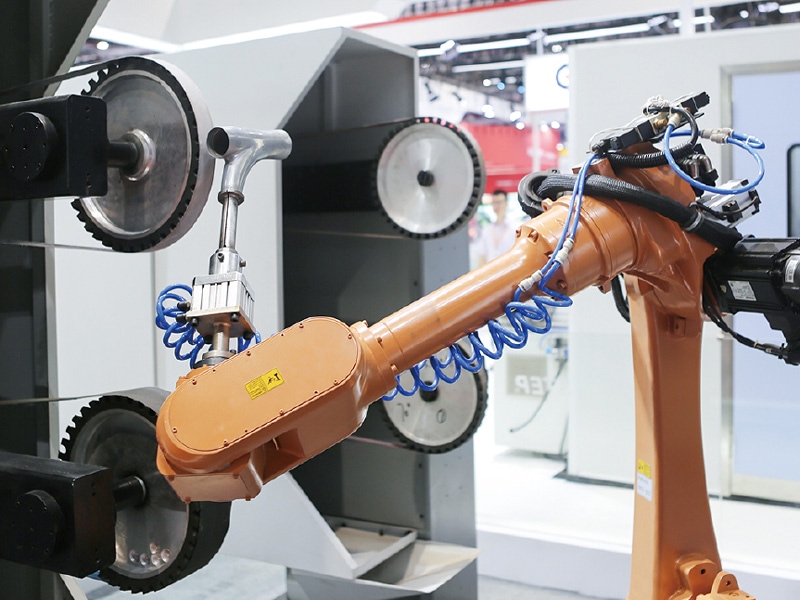

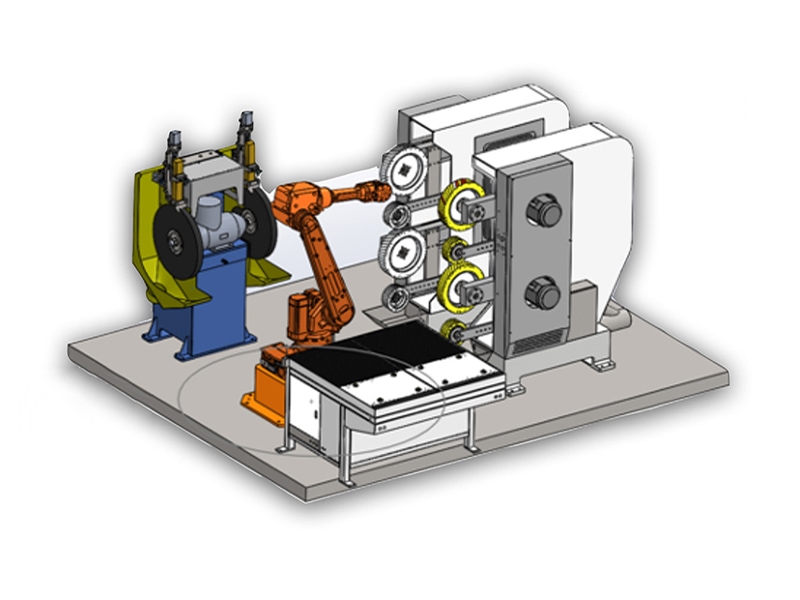

The faucet grinding unit workstation polishes and draws the faucet, using an integrated workstation composed of a robot, a force-controlled multi-functional sanding belt machine, and a loading and unloading table.

Use a manual loading table to load materials. Press the loading completion button. The robot will pick up the products in order for grinding and polishing, then return them to the initial position, and then manually unload the materials to complete the entire grinding and polishing process.

Scope of application: This station can be used for surface treatment of various types of bathroom hardware, zinc alloys, auto parts products, or glass and non-metallic products.

Robot polishing unit machine advantages

1: The robot can work continuously and stably, operating 24 hours a day

2: The program is stable and adjustable, and the polished surface quality is stable.

3: Robots reduce the safety risks of workers’ operations and are beneficial to factory management.

4: Use well-known robots with belt sanders, and the equipment is highly accurate.

5: The manipulator can automatically pick and place products and complete the overall polishing action.

6: Manipulator and abrasive belt combination, intelligent control system, improve efficiency

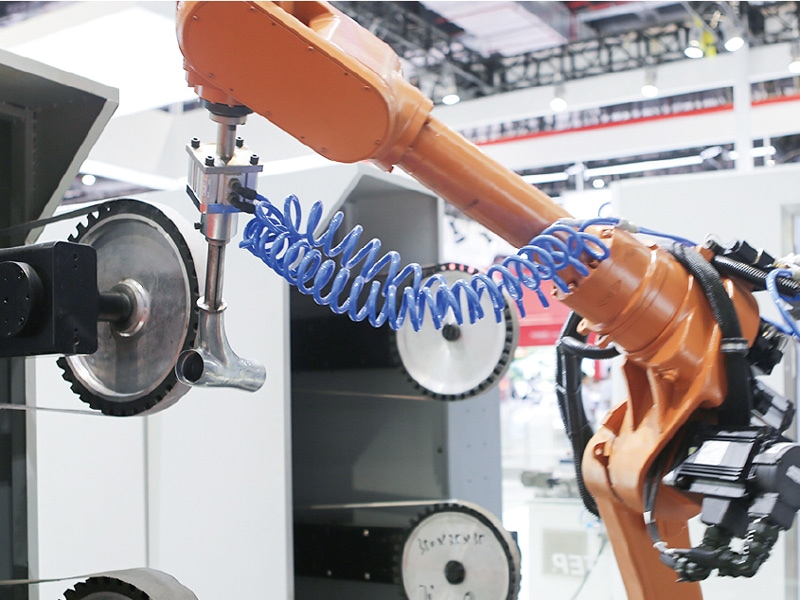

Advantages of belt sanding machine

1: The belt sanding machine has adjustable speed and automatic tightening function.

2: Fast response and powerful function.

3: The belt sanding machine adopts an automatic tightening mechanism, which can automatically adjust the tightness according to the length of the sanding belt, making the belt sanding machine stable and efficient, and it is also convenient and quick to replace the sanding belt.

KS after accumulating many cases, control every process and equipment in the workstation, and use mainstream brand robots to ensure the accuracy of grabbing workpieces every time.

After rough grinding, medium grinding, and fine grinding are carried out on the grinder, rough polishing, fine polishing and other steps are carried out. Its floating constant pressure mechanism and abrasive belt adjustment structure realize the integration of grinding and polishing.

Kingston will continue to provide advanced, intelligent and high-quality solutions for the manufacturing industry.