Flexible Polishing And Grinding Robot Workstation

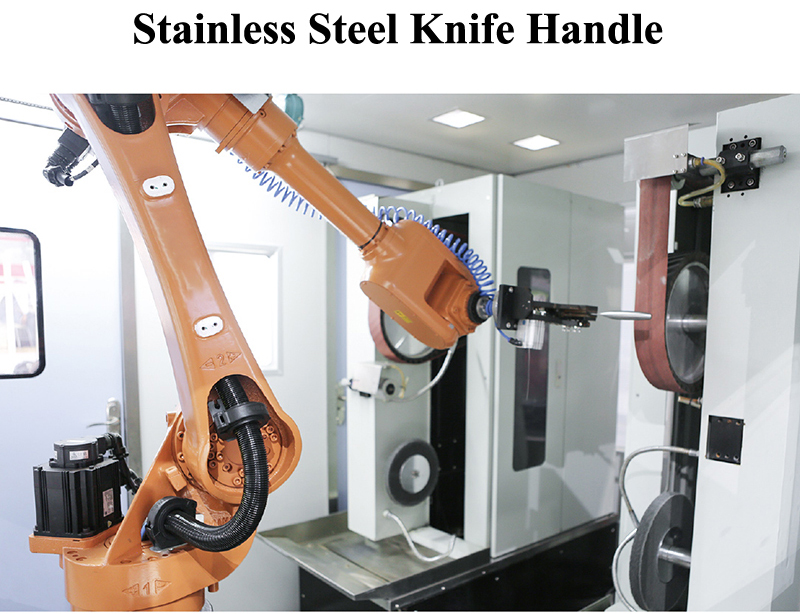

Flexible polishing and grinding robot workstation (Robot grabs workpiece)

Compared with traditional manual polishing, which has the disadvantage of being easily deflected and blurred, The KS robot polishing workstation uses advanced technologies such as real-time force control feedback, precision trajectory adjustment, and precision contact force adjustment to achieve safe, stable, and efficient polishing and grinding operations.

It overcomes the shortcomings of traditional robots such as being easy to hit by mistake, long debugging time, and inconsistent quality of finished products, so it has obvious differentiated advantages.

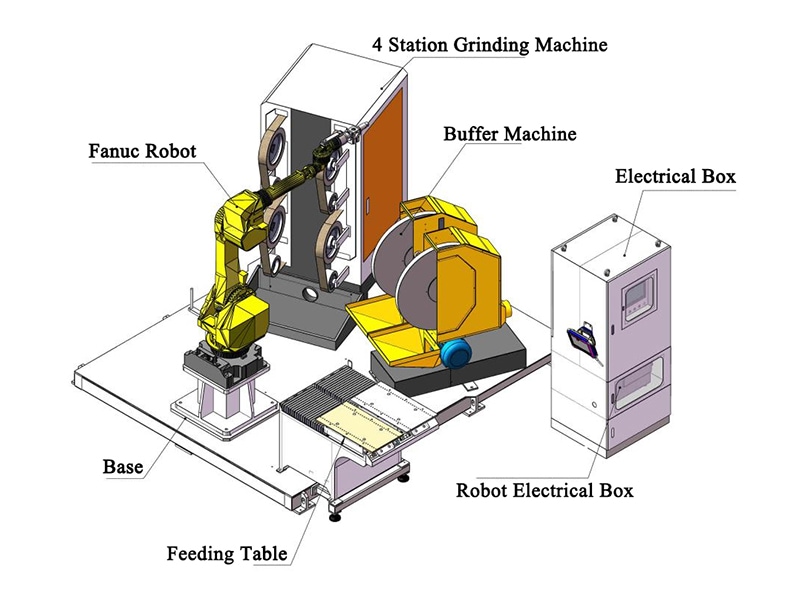

Flexible grinding robot workstation composition

1. Polish the robot body

2. Robot flexible perception neural network (tactile + vision)

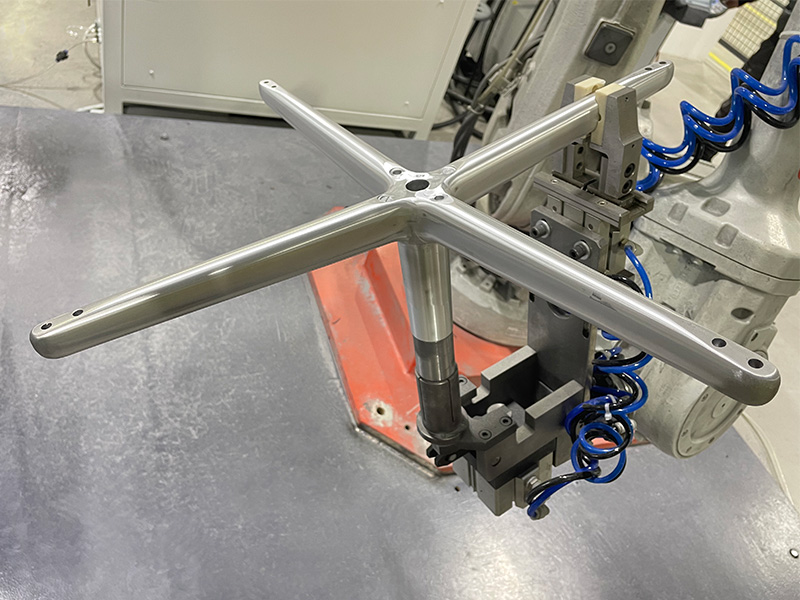

3. Robot end gripper

4. Process formula (grinding tool shape design + mesh number + number of grinding + power actuator + speed + torque + trajectory + flexible perception)

5. Force-controlled flexible belt machine

6. Dual-station rotary table (including clamping system)

7. Flexible grinding tool library

8. Offline programming software

9.STA flexible grinding system (Stial Rapid)

10. Visual monitoring system (OWL)

11. Intelligent after-sales system (MovS)

12. Central control system, dust removal system, safety protection system